Novel brake pad and mold and method for manufacturing same

A new type of mold and brake pad technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of industrial fertilizer waste, high cost, insufficient bonding force, etc., achieve stable and long-lasting friction effect, reduce brake noise, and brake low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

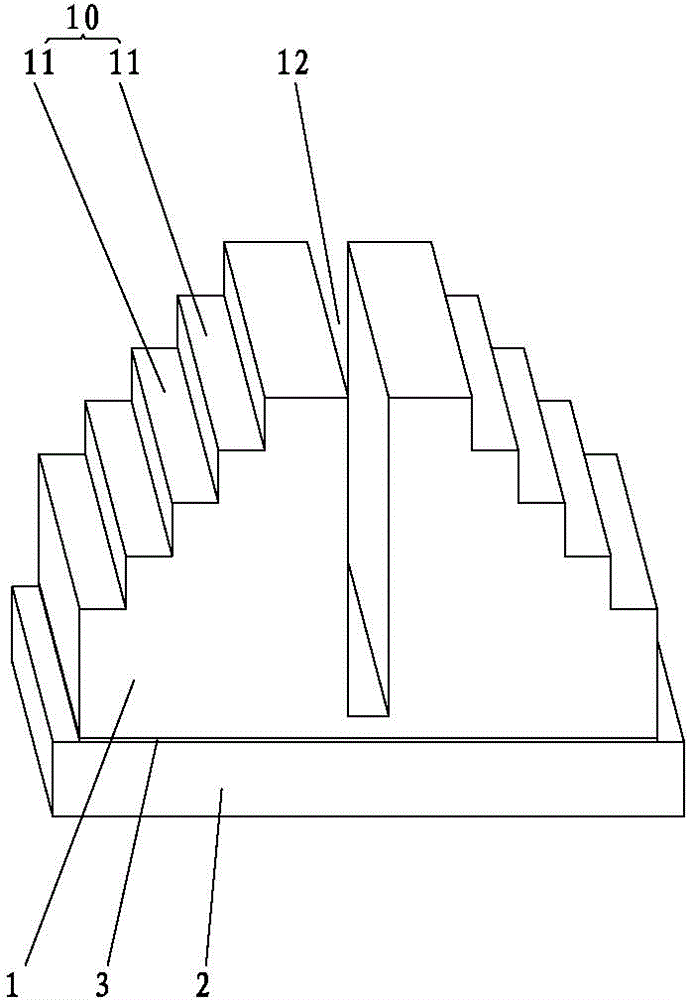

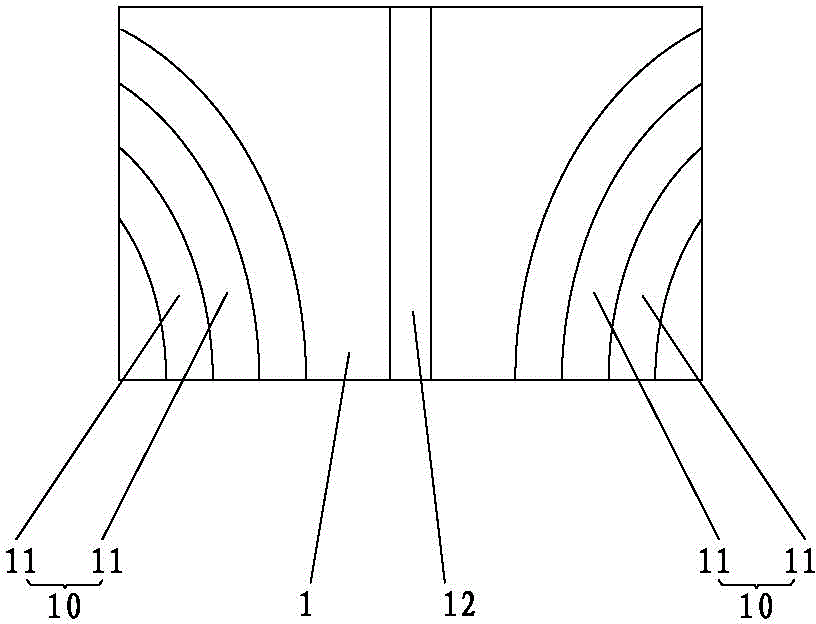

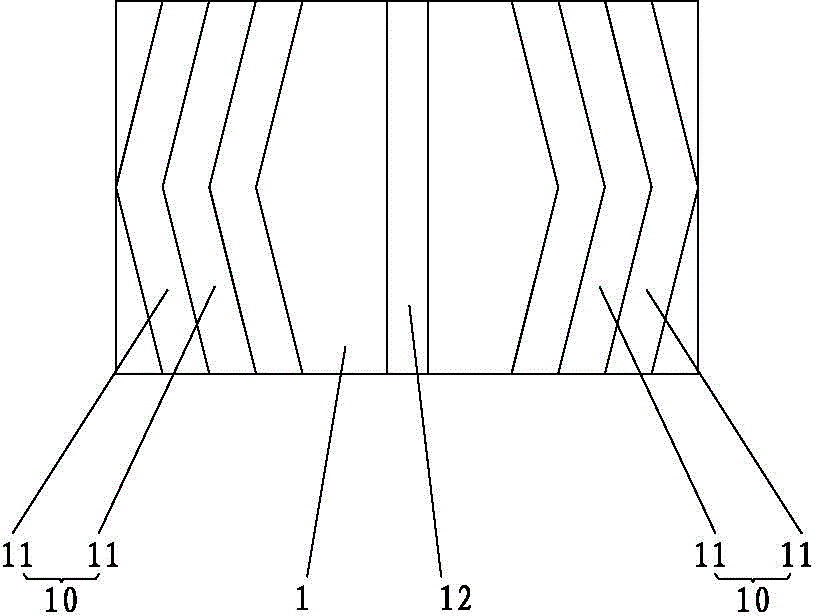

[0061] A novel brake pad of the present invention, such as Figure 1-10 As shown, a friction material block 1 is included.

[0062] The friction working surface of the friction material block 1 (the surface that rubs against the tire brake disc during braking) is formed with a plurality of stepped working surfaces 11 of different heights that rise or fall step by step. When the present invention is in use, the stepped working surface 11 that is raised or lowered step by step forms a chamfer in the form of a step. The chamfer in the form of a step can effectively reduce the braking noise, and at the same time efficiently remove wear debris, and As the friction material block 1 is used and consumed, the friction area with the tire brake disc (not shown in the figure) gradually increases, and the braking effect will not be poor due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com