Digital electronic detonator detonating network junction device

A digital electronic detonator and detonation network technology, which is applied in blasting and other directions, can solve the problems of overall shedding, lack of waterproofing, and affecting networking work, and achieve the effect of reasonable structure, convenient use, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

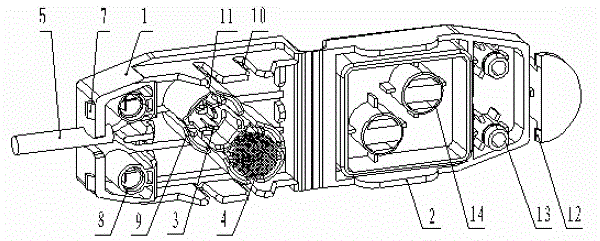

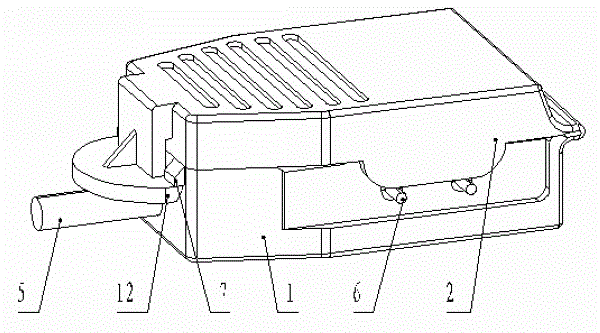

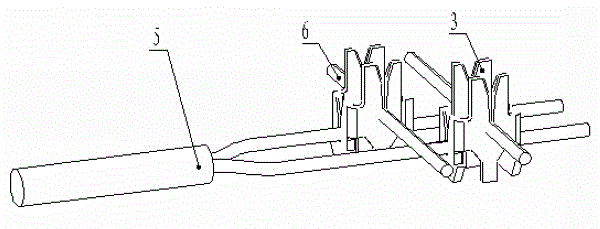

[0022] figure 1 Among them, the present invention includes a connecting body 1 and a pressing body 2 that are movably connected. The wiring body 1 is provided with two conduction devices 3 for conducting the detonator leg wires and the network blast zone wires, and each conduction device 3 is provided with detonator leg wires for piercing the insulation layer of the detonator leg wires 5 Knife-edge grooving, knife-edge grooving for network blasting zone wires used to pierce the insulation layer 6 of networking blasting zone lines, knife-edge grooving for detonator leg wires and network blasting zone line knife-edge grooving are two groups, thunder The knife-edge groove of the tube foot line is lower than the knife-edge groove of the network explosion area line, and the height difference is 2.5mm (the diameter of the detonator foot line and the network explosion area line are both 1mm), and the two detonator foot line knife-edge grooves are connected The line is perpendicular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com