Shadow Moire measuring system for automatic compensation of contrast of fringe pattern

An automatic compensation and measurement system technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of fringe contrast reduction in fringe patterns, affecting phase extraction and phase unwrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and example.

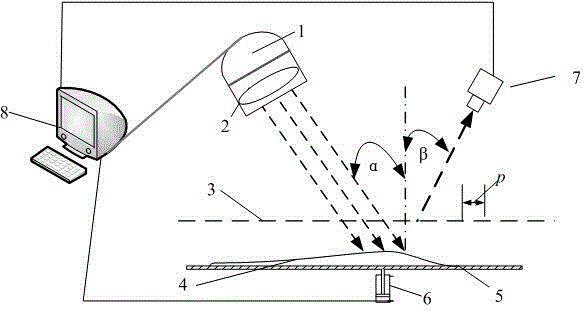

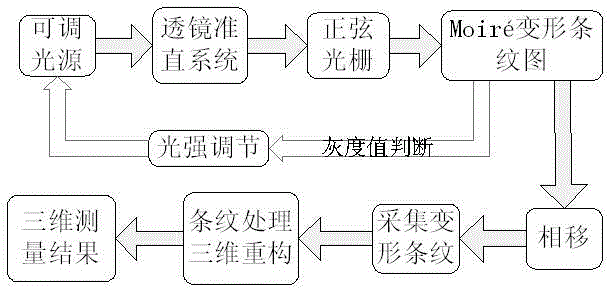

[0022] The fringe image contrast automatic compensation Shadow Moiré measurement system based on phase shift technology, including an adjustable light source 1 and a stage 5, the object 4 to be measured is arranged on the stage 5, and a sinusoidal grating 3 is arranged above the object 4 to be measured; The adjustable light source 1 projects parallel light through the lens collimation system 2 and illuminates the sinusoidal grating 3. The sinusoidal grating 3 overlaps the shadow grating modulated by the surface shape of the measured object 4 to form a moiré fringe pattern, and the generated moiré deformed fringe pattern passes through the CCD camera 7 The collected processing is transmitted to the control system 8 .

[0023] The sinusoidal grating 3 is parallel to the stage 5 .

[0024] The pitch of the sinusoidal grating 3 is P, wherein the pitch of P is 0.08 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com