A transformer oil gas detection device

A technology for oil and gas detection and transformers, which is applied in the field of transformer oil and gas detection devices, can solve problems such as hidden dangers, degradation of transformer insulation performance, and impact on insulation performance, and achieve the effects of low cost, improved safety, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

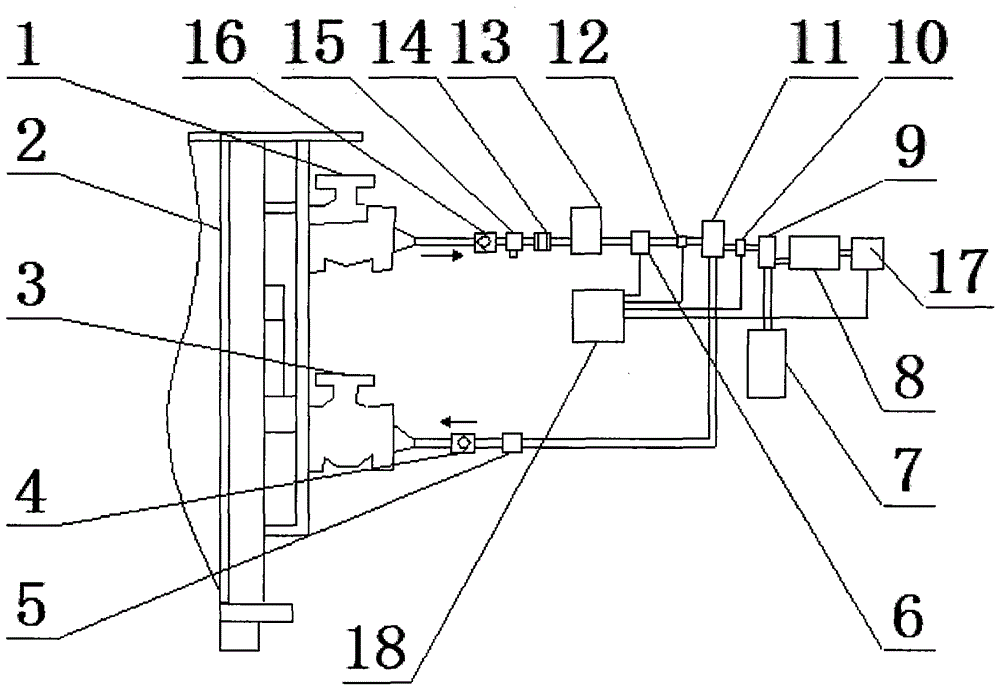

[0010] Such as figure 1 As shown, a transformer oil and gas detection device includes a transformer 2, a valve A1 and a valve B3 are arranged on the side wall of the transformer 2, and one side of the valve A1 communicates with the insulating oil inner cavity of the transformer 2, The other side of valve A1 is connected with check valve B3, sampling device 15, filter device 14, cooling device 13, oil pump 6, oil pressure detector 12, oil-gas separation device 11 in sequence; one side of valve B3 is connected with In the insulating oil cavity of the transformer 2, the other side of the valve B3 is connected with a one-way valve A4, an exhaust device 5, and an oil-gas separation device 11 in sequence; the oil inlet of the oil-gas separation device 11 is connected with an oil pressure detector 12, The oil outlet of the oil-gas separation device 11 is connected with the exhaust device 5, and the gas outlet of the oil-gas separation device 11 is connected with the air pump 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com