Limit trigger type platinum resistance temperature sensor

A temperature sensor, platinum resistance technology, applied in thermometers, thermometer parts, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve temperature monitoring failure, interference filtering accuracy and reliability limitations, open circuit To achieve accurate temperature sensing, avoid train operation accidents, and solve potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

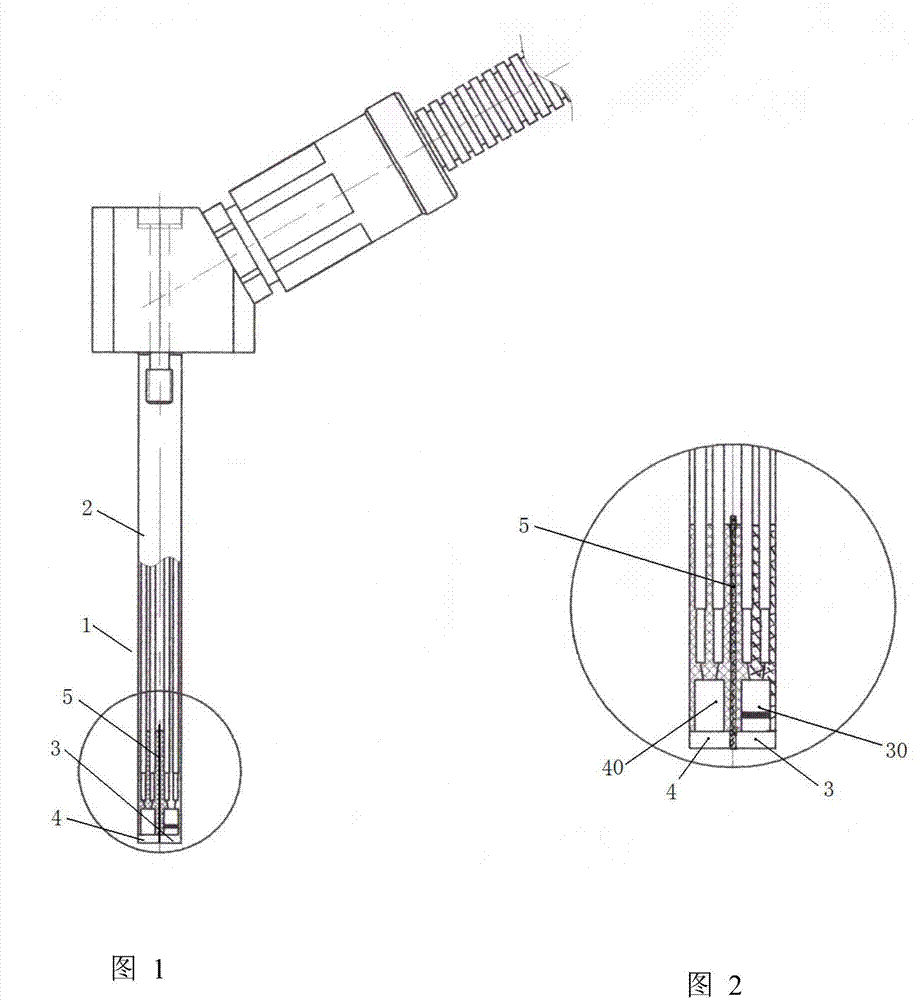

[0009] In the limit-triggered platinum resistance temperature sensor disclosed in the patent application of the present invention, a temperature measuring part 3 and a fusing part 4 are fixed side by side in the metal protective tube 2 of the temperature sensing probe 1, both of which are filled and fixed by heat-conducting and temperature-resistant insulating resin, and the temperature measuring part 3. The setting space and the setting space of the fuse part 4 are insulated and isolated by the central insulating partition 5. The insulating partition 5 is insulated and separated from the pipe end to the temperature measuring part 3 and the electric lead joint of the fuse part 4, so that there is sufficient insulation creepage between the two. distance, to ensure the insulation performance of both. The temperature measuring part is an insulating and encapsulated platinum resistance temperature sensing core 30 and its electrical lead connectors. After the platinum resistance tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com