Photoelectric composite cable

A photoelectric composite cable and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor shielding performance, simple cable structure, unsatisfactory, etc., and achieve the effect of strong shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

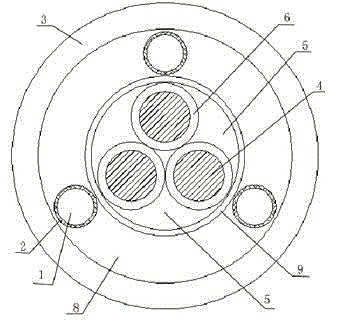

[0015] A photoelectric composite cable, which is characterized in that it includes at least three conductors 4, and the conductors are wrapped with an insulating layer 6, and all conductors 4 wrapped with the insulating layer 6 are wrapped with a shielding layer 9, and the gap between the shielding layer 9 and the insulating layer 6 filler 5, the shielding layer 9 wraps the inner sheath layer 8, the inner sheath layer 8 is provided with at least three optical fibers 1, the optical fiber 1 is wrapped with a water blocking layer 2, and the inner sheath layer 8 is wrapped There is an outer sheath layer 3 .

[0016] The water-blocking layer 2 includes a reinforcing layer, a base layer, a water-blocking layer and a covering layer bonded in sequence, the reinforcing layer is a copper wire mesh, the base layer and the covering layer are both non-woven fabrics, and the water-blocking layer is made of mica tape or glass The fiber and the water blocking layer 2 are not allowed to deform...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap