Key manufacturing method and key manufactured by using method

A production method and key technology, applied in layers, legends, electrical components, etc., can solve problems such as shortening the stocking cycle, unfavorable characters for manufacturers to stock up in advance, and reducing inventory pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention discloses a manufacturing method of a button, which is suitable for portable electronic devices such as mobile phones and PDAs. In this embodiment, a button assembly applied to a mobile phone is taken as an example for illustration.

[0025] see Figure 1 to Figure 3 , the manufacturing method of the button of preferred embodiment of the present invention comprises the following steps:

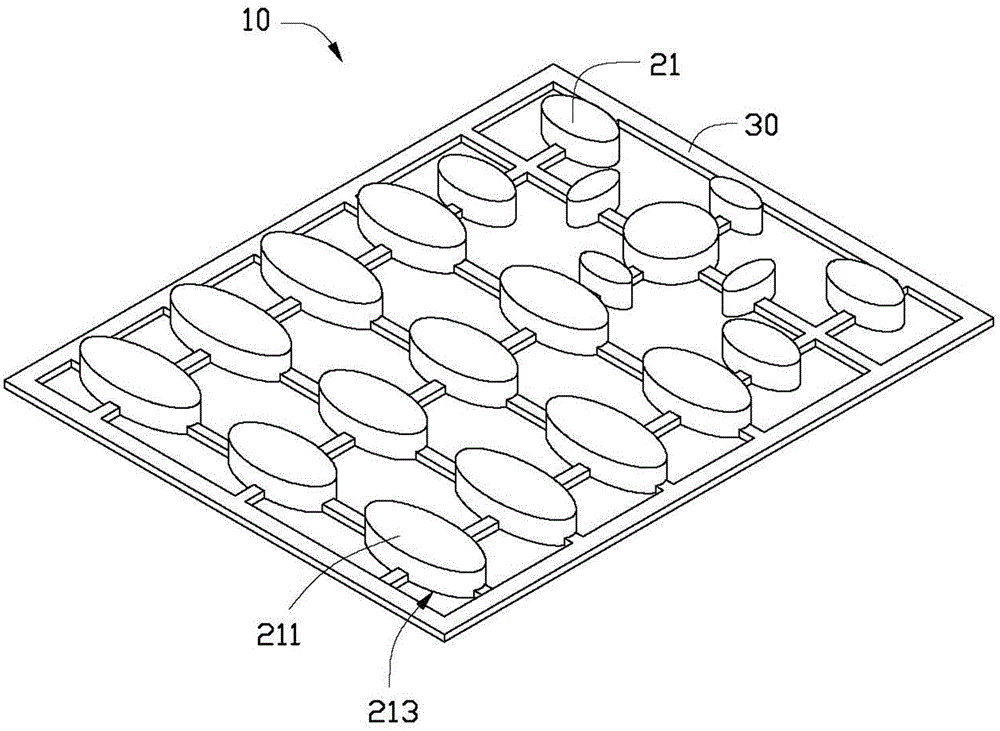

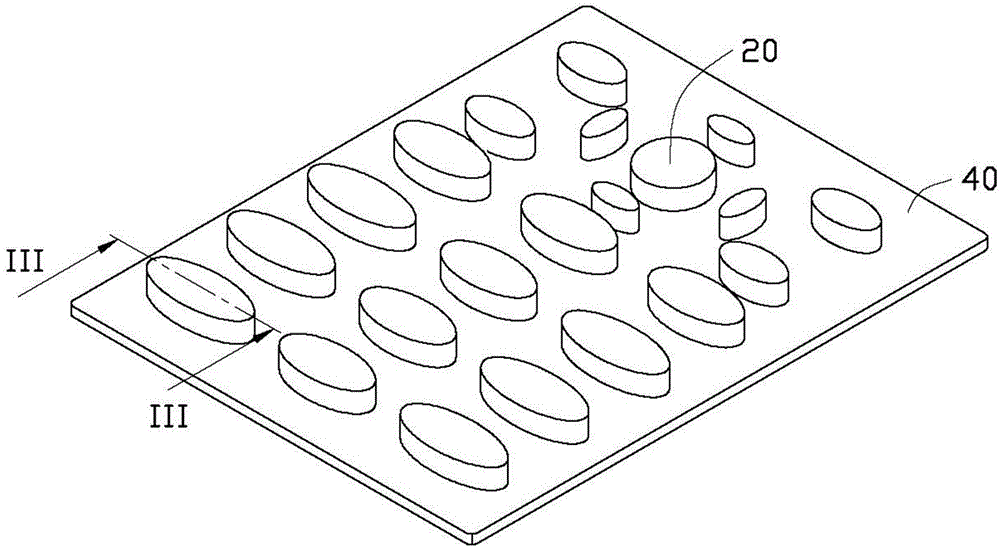

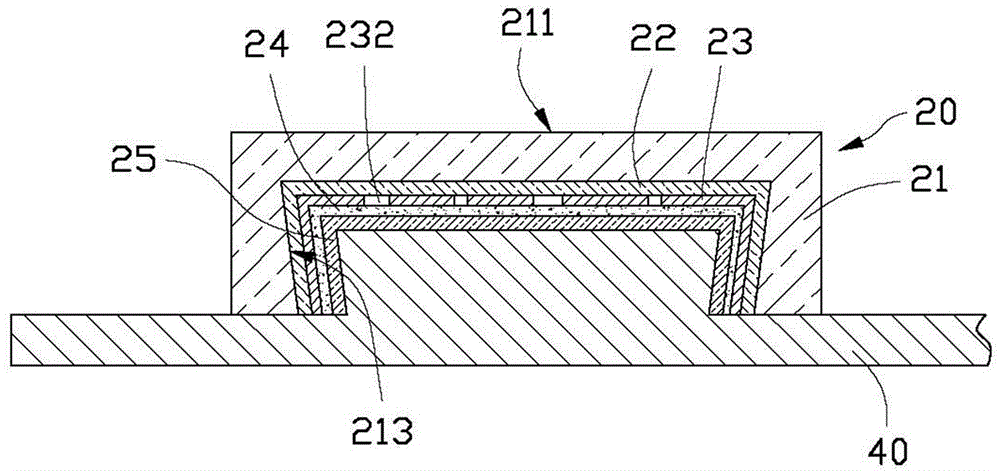

[0026] Injection molding a button substrate 10 . The key substrate 10 includes a plurality of key bases 20 and a mesh connecting portion 30 connecting the plurality of key bases 20 together. The injection molded material is a transparent plastic such as polycarbonate. The button base 21 includes a top surface 211 and a bottom surface 213 opposite to the top surface 211 . The top surface 211 refers to the surface on which the button is pressed and operated after it is assembled in the portable electronic device.

[0027] A transparent primer is sprayed or printed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com