Composite intelligent high power arc-free direct current bus contact device

A technology of DC bus and contact device, which is applied in the field of medium voltage and high voltage high power DC switches and high power DC switches to avoid the risk of thermal hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

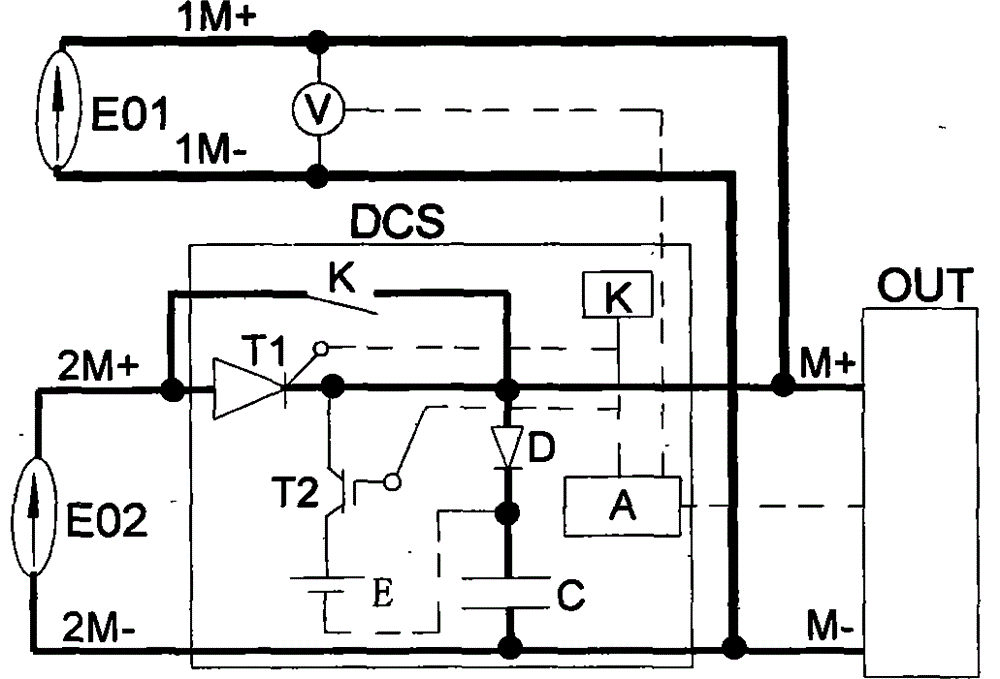

[0011] Such as image 3 As shown, the composite intelligent high-power arc-free DC bus contact device DCS is composed of a controller A, a contact main switch K, a non-contact main switch T1 and its dynamic reverse bias control circuit. The dynamic reverse bias control circuit It consists of non-contact control switch T2, voltage source E, capacitor C and diode D. The positive pole of T1 is connected at the same point as the positive pole of the busbar of the emergency DC power supply E02 and the input end of the K main contact, the negative pole of T1 is connected to the output end of the K main contact, the negative pole of T2, the positive pole of the diode D, and the positive pole M+ of the output busbar Common point connection, the negative pole of the diode D is connected to the positive pole of the capacitor C and the negative pole of the voltage source E, the positive pole of the voltage source E is connected to the positive pole of the non-contact control switch T2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com