Magnetic coupling resonant multi-joint combination non-contact safety socket-plug

A non-contact, safety socket technology, applied in the direction of electromagnetic wave systems, electrical components, circuit devices, etc., can solve the problems of mechanical wear, insecurity, and inflexibility, and achieve the effect of simple manufacturing and processing, easy portability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will be further described in detail through specific embodiments in conjunction with the accompanying drawings.

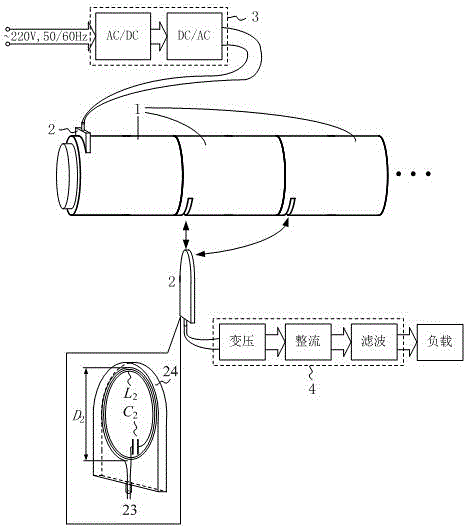

[0017] The embodiment of the present invention is a magnetically coupled resonant multi-section combined non-contact safety socket and plug with a power supply of 220V, 50Hz / 60Hz mains and a circular cross section.

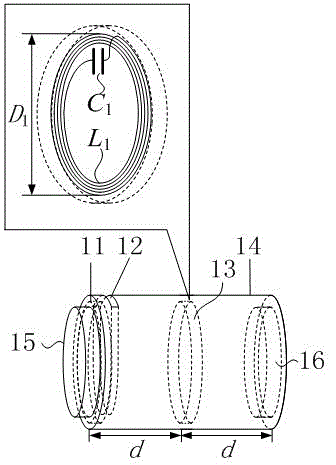

[0018] from Figure 1 to Figure 2 It can be seen from the shown embodiment of the present invention that the combined socket is formed by connecting and combining a plurality of socket unit columns 1 with the same specifications, and each socket unit column includes two LC resonators 11 and 13, a slot 12, and a socket insulating shell 14, One end of the socket insulating shell 14 is a socket unit post connector 15 , and the other end is a socket unit post connection groove 16 . The shell 14 plays the role of encapsulation, insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com