Initial startup method for biaxial contra-rotating permanent-magnet brushless direct-current motor

A permanent magnet brushless DC, a pair of technology, applied in the direction of the starter of a single DC motor, the deceleration device of the AC motor, the motor generator/starter, etc., can solve the problems that the invention cannot be realized, the description is not clear, etc., to achieve No start-up dead zone problem, avoid table look-up method, accurate calculation of angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

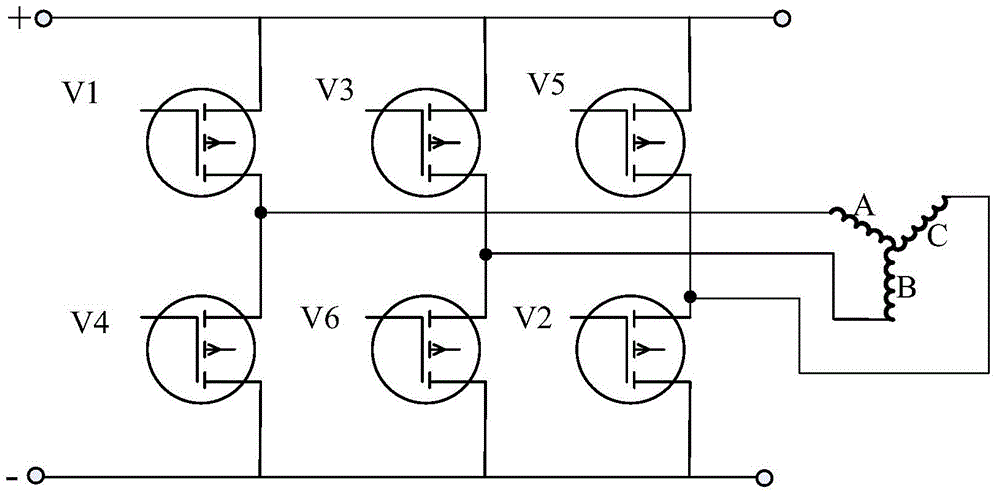

[0054] Such as image 3 The shown dual-axis counter-rotating permanent magnet brushless DC motor drive control system consists of DSP, CPLD, IPM, position detection module, voltage and current detection module, voltage conversion module, and communication module.

[0055] Formulate the first stage commutation control table

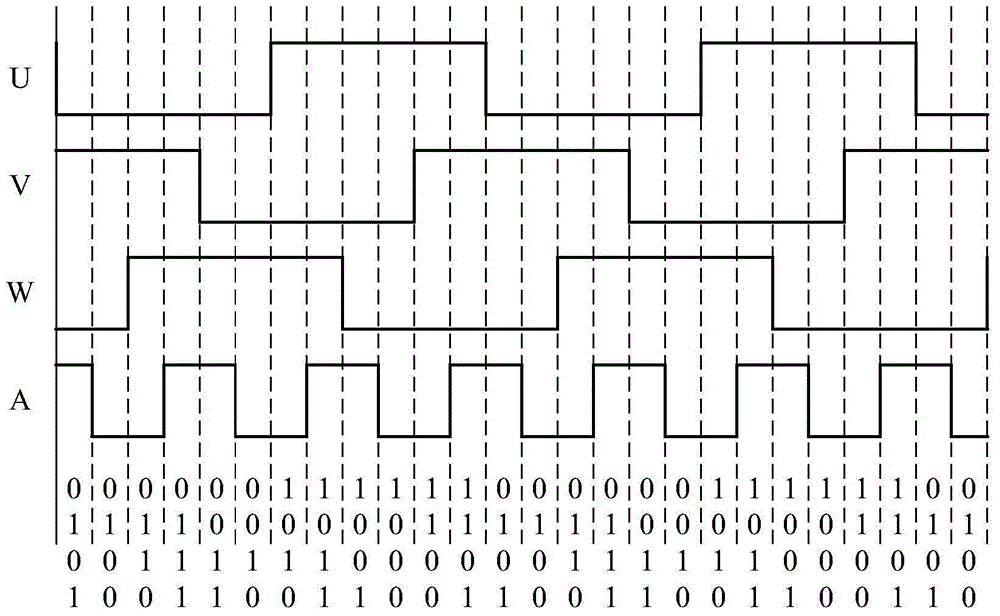

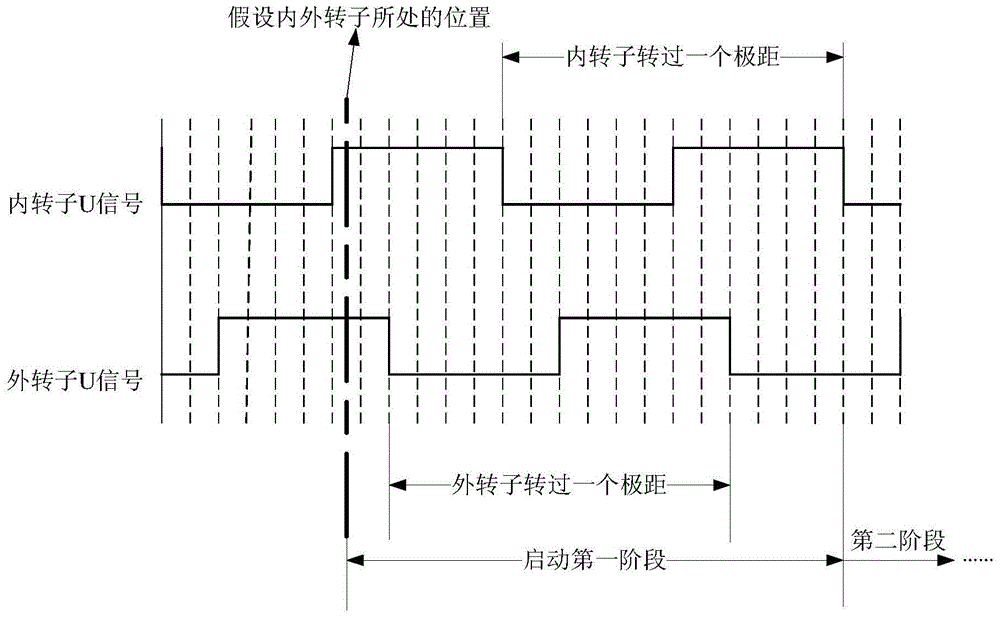

[0056] Step 1. According to the position signals of the inner rotor U, V, W, A, compile the inner rotor state code D, 0≤D≤11, D∈N;

[0057] Step 2. Prepare the outer rotor position code Z according to the outer rotor U, V, W, and A position signals, 0≤Z≤11, Z∈N;

[0058] Step 3. Superimpose the angle intervals of the inner and outer rotors, that is, θ=θ 1 +θ 2 , if θ≥360°, let θ=θ-360°;

[0059] a. IF 0°≤θ<60°C=0;

[0060] b. IF 60°≤θ<120°C=1;

[0061] c. IF 120°≤θ<180°C=2;

[0062] d. IF 180°≤θ<240°C=3;

[0063] e. IF 240°≤θ<300°C=4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com