Cleaning machine for surface softening overflowing material of transistor

A cleaning machine and transistor technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of high labor intensity, low production efficiency, low cleaning quality, etc., to reduce labor intensity, Safe and simple operation and smooth operation of the unit

Inactive Publication Date: 2015-05-27

修建东

View PDF5 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After chemically softening the overflow of plastic packaged transistors, the operator uses a brush to clean the softened plastic packaged transistor overflow. Disadvantages such as low cleaning quality, high labor intensity, and low production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

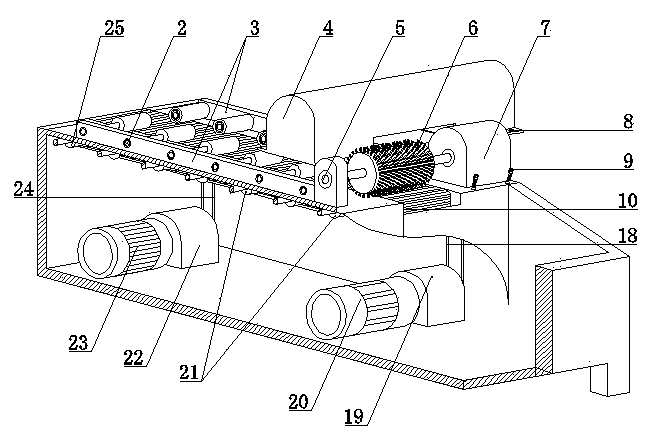

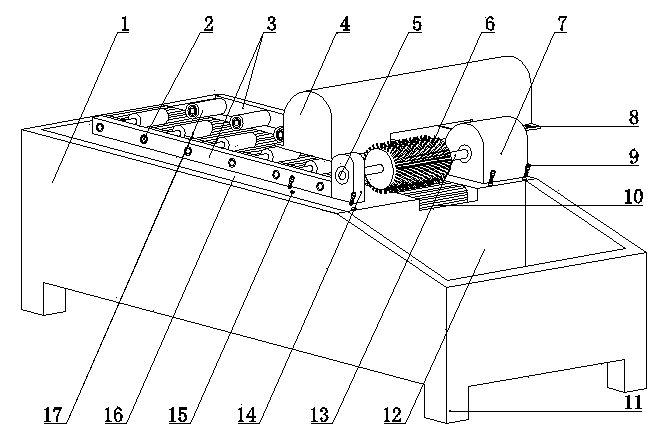

The invention discloses a cleaning machine for a surface softening overflowing material of a transistor. The machine comprises a machine body, a fixing shaft, a baffle, a splash preventing cover, a bearing, a roller brush, a gearbox, a mounting hole, a bolt, a conveyor belt, a collecting box, a bottom pin, a rotating shaft, a bearing block, a screw hole, a table top, a pressing roller, a chain, a transmission, a speed regulating motor, a main rotating shaft, a driven rotating shaft, a reduction gearbox, a motor and a triangular belt. When in use, a power supply is turned on, the rotating speed of the speed regulating motor is adjusted to be proper speed, a transistor belt is positioned on the conveyor belt at the left end of the cleaning machine to be conveyed to be below the roller brush under the effects of the driving rotating shaft, the driven rotating shaft and the pressing roller, the speed regulating motor drives the roller brush to rotate, a plastic brush arranged on the roller brush is used for quickly cleaning the surface softening overflowing material of the transistor, and the cleaned transistor belt is conveyed into the collecting box through the conveyor belt. According to the cleaning machine, the automatic cleaning mode is adopted, so that the operation is safe and simple; the device runs smoothly, thus the working efficiency is increased, and the labor intensity is reduced; the cleaning machine is suitable for industrial production.

Description

technical field The invention relates to the field of industrial treatment tools for transistor surfaces, in particular to a transistor surface softening and overflow cleaning machine. Background technique At present, China has become one of the fastest growing and most used transistor markets in the world. The typical transistor packaging process is: scribing, chip loading, bonding, plastic packaging, deflashing, electroplating, printing, rib cutting, and visual inspection , testing, and packaging for shipment. Flashing is a common quality problem in the packaging process. Flashing will form flashes, attach wiring pins, and heat sinks, which will affect the appearance, solderability, and heat dissipation of the finished transistor. Reducing the occurrence and removal of flash is a topic discussed and valued by packaging engineers, electroplating engineers, material manufacturers and mold manufacturers. After chemically softening the overflow of plastic packaged transistors...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): B08B1/02H01L21/02B08B1/20

CPCH01L21/02057B08B1/20B08B1/32B08B1/12

Inventor 修建东

Owner 修建东

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap