Laser airtight welding process-based packaged structure of high-frequency microwave product and manufacturing method for package structure

A high-frequency microwave and welding process technology, applied in the field of packaging structure design of high-frequency microwave products, to achieve the effects of anti-corrosion packaging, providing mechanical strength and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The packaging structure and method of high-frequency microwave products based on the laser hermetic welding process according to the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

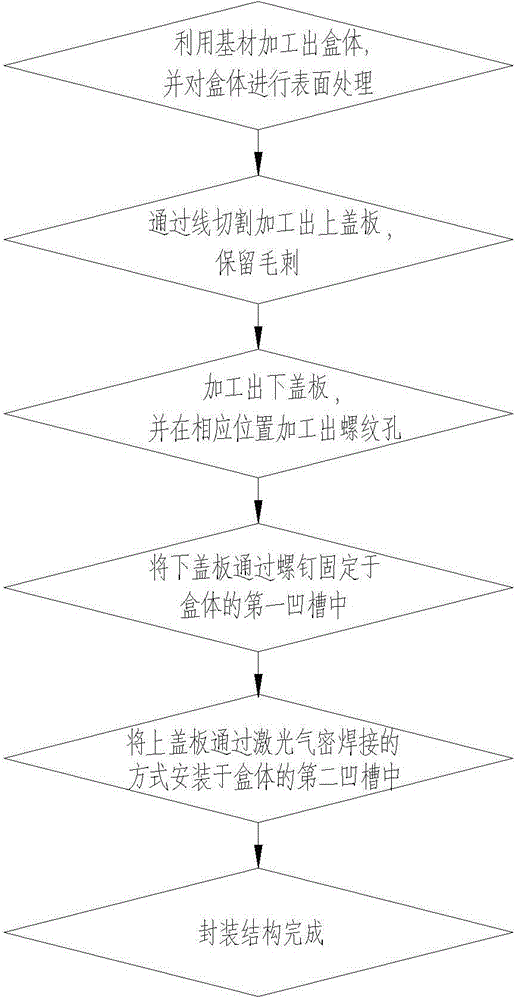

[0020] The packaging structure and the manufacturing method thereof of the present invention are mainly based on the adoption of laser airtight welding technology. The laser sealing welding process can well solve the defects and deficiencies of the conventional welding process for high-frequency microwave products, such as: unreliable air tightness, excessive welding residue, and limited welding materials. Due to the particularity of laser hermetic welding, there are special requirements for the structural design of the product. Aiming at this requirement, the present invention designs the encapsulation structure.

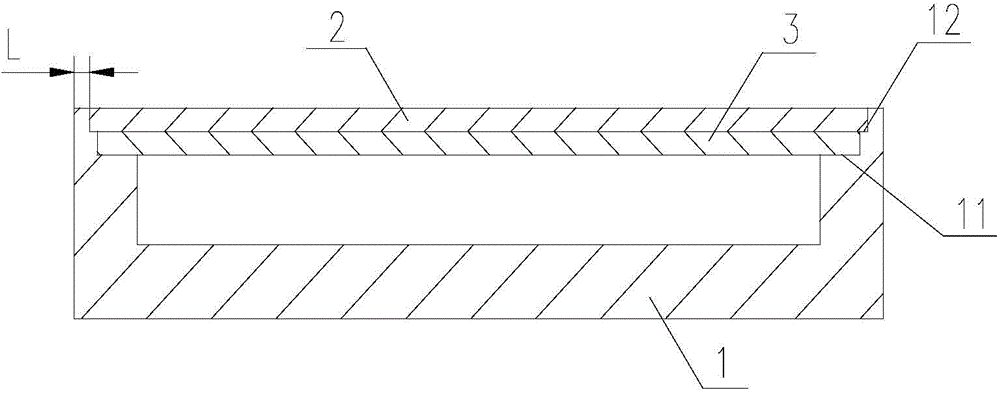

[0021] Such as figure 1 As shown, the high-frequency microwave product packaging structure ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com