Experimental device and experimental method of superheated steam distillation of thickened oil

A technology of superheated steam and experimental device, which is applied in the distillation control/regulation of hydrocarbon oil, hydrocarbon distillation, petroleum industry, etc., and can solve problems such as unclear details

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

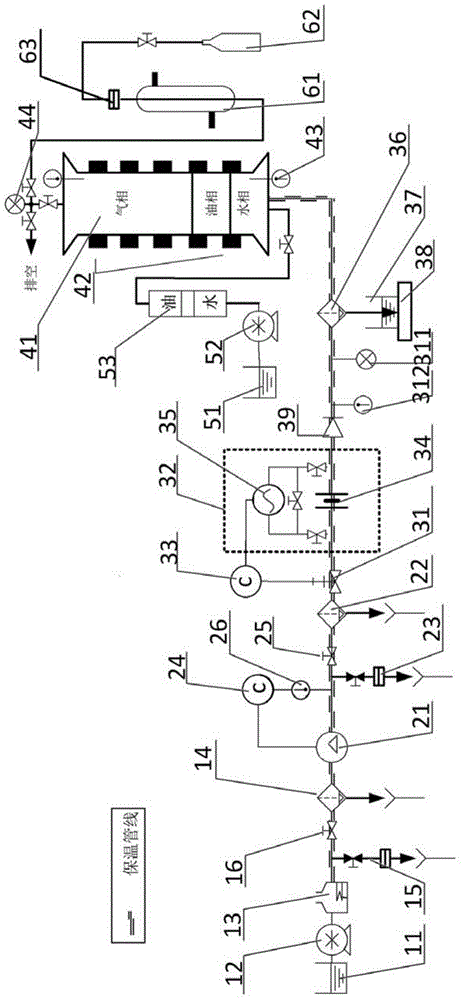

[0052] This embodiment provides an experimental device for superheated steam distillation of heavy oil, such as figure 1 As shown, the device includes a steam generation unit, a heating unit, a metering unit, a still, a liquid phase collection unit and a gas phase collection unit.

[0053] The steam generation unit includes a water storage tank 11, a water pump 12, a steam generator 13, a first valve 16, a first bypass line 15 with a back pressure valve, a first gas-liquid separator 14, and the water storage tank 11 , the water pump 12, the steam generator 13, and the first gas-liquid separator 14 are connected in sequence, and the first bypass line 15 with a back pressure valve is arranged between the steam generator 13 and the first gas-liquid separator. The first valve 16 is arranged between the first bypass line 15 with a back pressure valve and the first gas-liquid separator 14 .

[0054] The heating unit includes a heater 21, an automatic heating controller 24, a thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com