Automatic control system of automatic brush washer

An automatic control system and brush washing machine technology, applied to the control device of washing machine, brush washing machine, other washing machines, etc., can solve the problems of not achieving the ideal effect, difficult to clean, time-consuming and labor-intensive, etc., and achieve high cleaning efficiency , good cleaning effect, simple operation and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with drawings and embodiments.

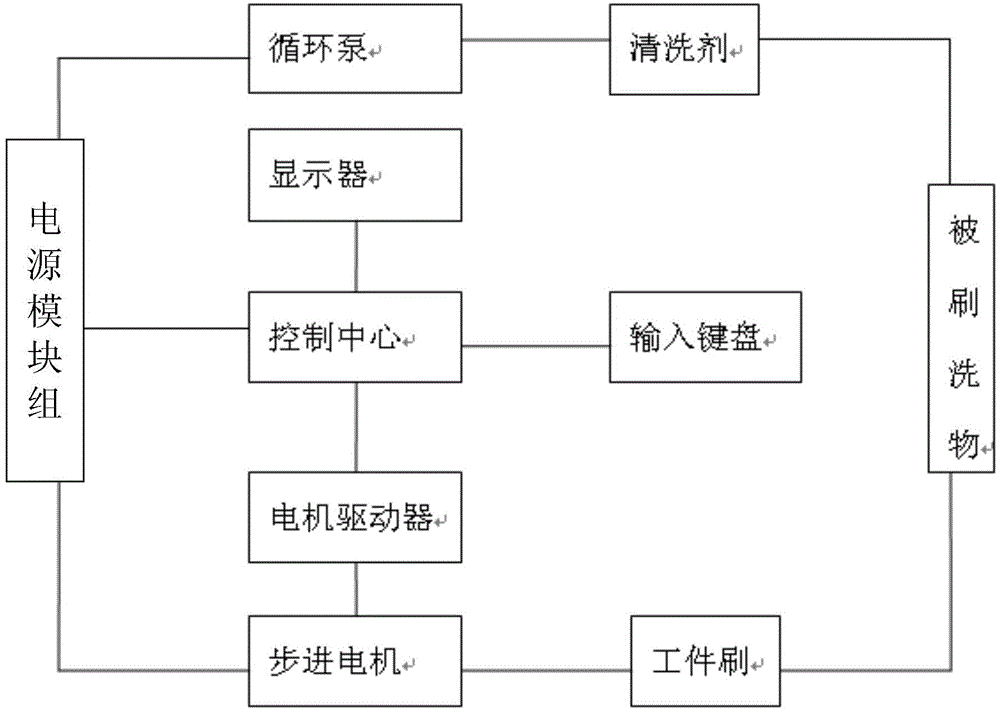

[0011] Please refer to figure 1 As shown, the embodiment of the present invention includes a power module group, and the power module group includes a 220v / 60v step-down module, a 220v / 12v step-down module, and a 12v / 5v step-down module. The embodiment of the present invention also includes a stepper motor driver, Stepper motors, control centers, displays, input keyboards, circulation pumps, cleaning agents, workpiece brushes and brushed laundry. The 220v / 60v step-down module in the power module group is used to supply power to the stepper motor driver and the stepper motor, and the 220v / 12v step-down module is connected to the 12v / 5v step-down module to supply power to the control center and display. The 220v voltage directly controls the circulation pump. The circulation pump controls the flow rate of the cleaning agent during scrubbing, and transports the cleaning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com