Water-discharging noise-lowering asphalt pavement structure of cement concrete bridge deck and laying process

A technology for cement concrete and asphalt pavement, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, and can solve problems such as performance degradation such as anti-skid, drainage and noise reduction, shortened service life of bridges, hidden dangers and other problems. Improve the anti-skid performance and driving safety performance, prolong the service life, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

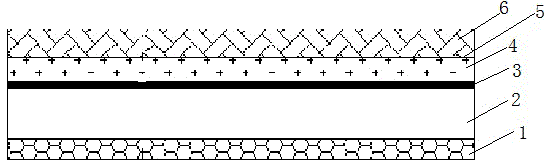

[0031] like figure 1 As shown, the drainage and noise-reducing asphalt pavement structure for cement concrete bridge deck pavement of the present invention includes a waterproof bonding layer 2, a buffer layer 3, a paving lower layer 4, an adhesive layer 5 and a paving layer laid in sequence from bottom to top. The surface layer 6 and the waterproof bonding layer 2 are laid on the cement concrete bridge deck 1 .

[0032] The pavement surface layer 6 has a thickness of 5 cm, and is specifically OGFC-13 open-graded asphalt mixture, which is composed of rubber asphalt, coarse aggregate, fine aggregate, mineral powder and external admixture. Rubber asphalt is used as the asphalt binder, wherein the rubber asphalt is blended with 60 mesh rubber powder and No. 70 base asphalt, and the rubber powder content is 20%; the gradation adopts open gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com