Combined type channel steel support template rod system and construction method thereof

A combined and channel-steel technology, applied in formwork/formwork/work frame, excavation, infrastructure engineering, etc., can solve problems such as complicated reinforcement process, easy deformation of formwork, and easy grout leakage in hole positions, so as to improve construction efficiency and quality, easy on-site operation, and flexible formwork support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

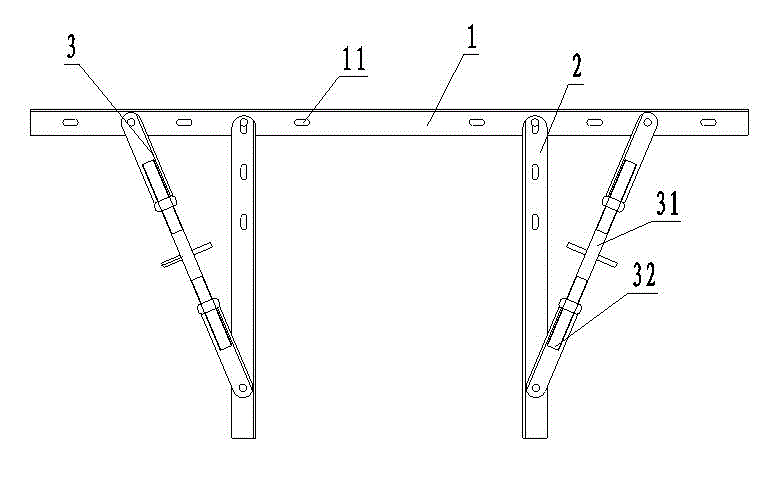

[0026] Example 1, such as image 3 , 4 As shown, it is the combined channel steel formwork rod system used for the frame beam of the road slope support, which is to pour a single-sided low wall. The upper beam 1 is composed of 12.6# channel steel, which is connected with two columns 2 (angle steel) through fasteners 4 (bolts and nuts) to form a formwork fixing groove, and the diagonal braces 3 on both sides (angle steel ) is connected with the upper beam 1 at one end through the fastener 4, and connected with the column 2 at the other end, and the length of the diagonal brace 3 is adjustable. The adjustable length of the diagonal strut 3 means that the middle part of the diagonal strut 3 is a screw rod 31, and the two ends are hollow connecting rods 32. One end of the hollow connecting rod 32 has a fixing hole 11, and the other end is a screw rod 31. nuts. The hollow connecting rod 32 is an angle steel, and one end is welded with a nut (or processed with an internally threa...

Embodiment 2

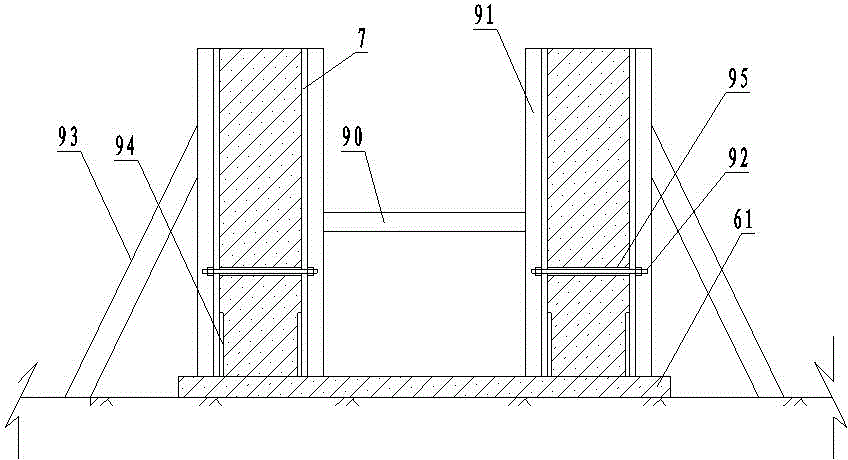

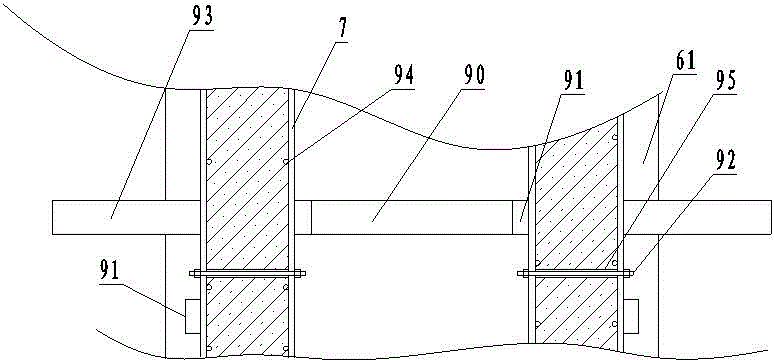

[0028] Example 2, such as Figure 5 , 6 , 7, a road side ditch combined channel steel formwork rod system structure, it is improved on the basis of the above-mentioned unilateral wall, the upper beam 1 and four columns 2 are connected by fasteners 4 to form a formwork Fixed groove, the diagonal struts 3 on both sides are connected to the upper beam 1 through the gasket 41 at one end of the fastener 4, and the other end is connected to the column 2 on the side. The thickness of the gasket 41 is the same as that of the column 2, so that Ensure that the diagonal struts 3 are evenly stressed, and the two adjacent columns in the middle are connected with a horizontal support 5, and the length of the horizontal support 5 is adjustable. The adjustable length of the horizontal support 5 means that the middle part of the horizontal support 5 is The screw rod 31 has hollow connecting rods 32 at both ends, and one end of the hollow connecting rod 32 has a fixing hole 11, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com