Hollow slab beam and preparation method thereof

A technology of hollow plate girders and beams, which is applied in the direction of bridges, manufacturing tools, bridge parts, etc., can solve the problems of reducing the height of slopes on both sides, achieve good overall mechanical performance, improve structural mechanical performance, and facilitate the installation of telescopic devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

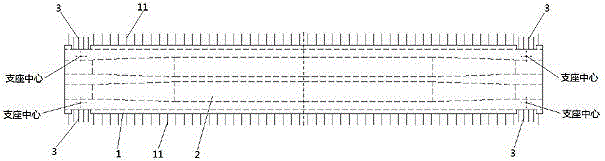

[0032] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

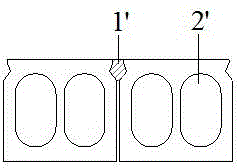

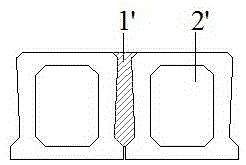

[0033] Such as Figure 3-Figure 6 A hollow slab girder is shown, comprising: a rectangular body 1, the rectangular body 1 includes an inner chamber 2 with variable cross-section; The end is provided with a crossbeam steel bar 3, the inner cavity 2 runs through the rectangular body 1, and is parallel to the length direction of the rectangular body 1; the prestressed steel beam 4 is arranged below the inner cavity 2, and It is located at the bottom of the rectangular body 1 and is parallel to the length direction of the rectangular body 1 .

[0034] The inner cavity 2 is molded by an inflatable capsule with variable cross-section; that is, the size of the end of the inner cavity 2 is smaller than the size of the middle part of the inner cavity. The thickness of the seat section web and the thickness of the top an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com