Large-span deck type cable auxiliary beam arch combined rigid frame bridge and construction method thereof

A cable-assisted girder and long-span technology, applied in arch bridges, infrastructure engineering, bridges, etc., can solve the problems of increased axial pressure and negative bending moment at the root of the main girder, small force component of the main body of the bridge, and unfavorable construction costs. , to achieve the effect of improving bearing efficiency, overcoming cracking and deflection, and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

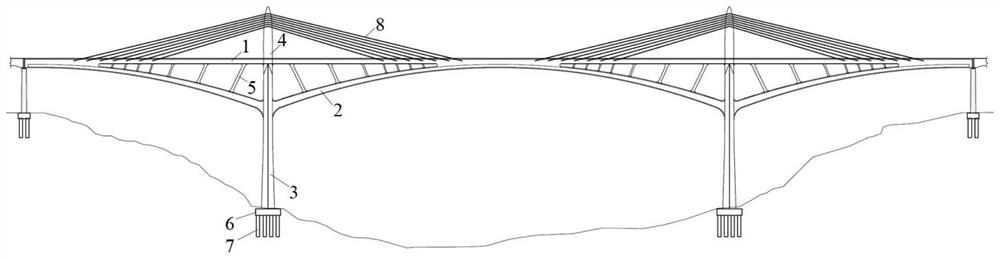

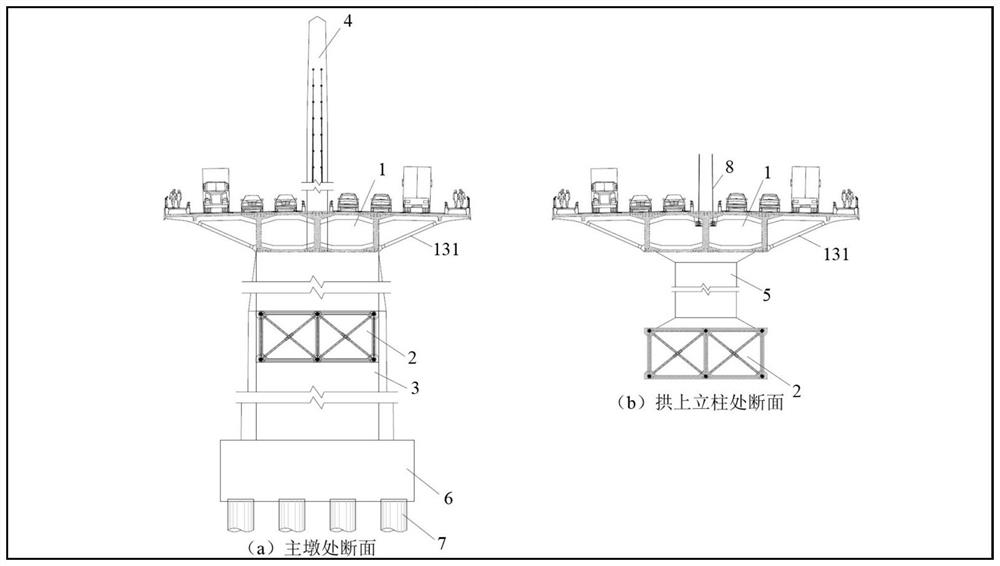

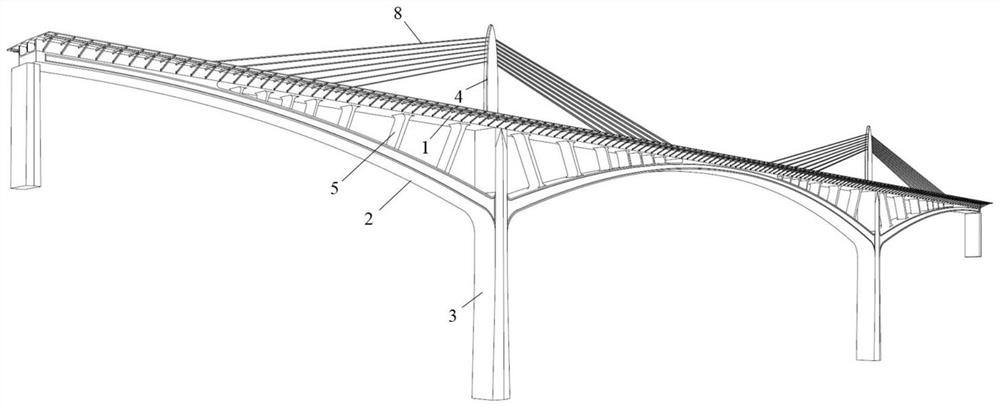

[0045] The large-span top-supported cable-assisted beam-arch composite rigid frame bridge in this embodiment includes hollow pier 3, upper chord box girder 1, lower chord box girder 2 supporting upper chord box girder 1, and hollow pier 3 and upper chord box girder 1. The upper cable tower 4 and the stay cables 8 distributed along the cable tower in the area of the beam-arch joint section 13 formed by the confluence and intersection of the upper string box girder 1 and the lower string box arch 2, the upper string box girder 1, the lower string box arch 2 and the hollow pier 3 intersect to form a beam-arch triangular area, the upper string box girder 1 is supported by hollow pier 3 and arch upper column 5 in the beam-arch triangular area, and the hollow pier 3 intersects with the arch feet of the lower string box arch 2 of the side span and mid-span , the upper column 5 of the arch is evenly distributed on the vertical surface perpendicular to the lower string box arch 2; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com