Outer shield arrangement structure for steel casings

A technology of steel casing and outer shield, which is applied in basic structure engineering, construction, sheet pile wall, etc., can solve the problems of large waste, heavy construction preparation work, and inability to fully recover the steel casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

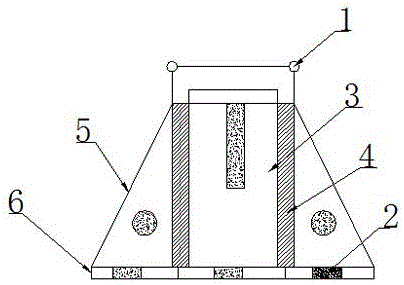

[0012] Example: such as figure 1 As shown, the present invention provides a steel casing plus an outer shield structure, including a suspension ring 1, a steel bar blade foot 2, a steel casing 3, a steel reinforcement skeleton 4, a water body 5 and a silt area 6; the suspension ring 1 is arranged on the overall The tops of the left and right sides are connected with the steel casing 3 through steel wire ropes; the steel bar blade feet 2 are arranged at the bottom of the whole, and are welded together vertically; the steel casing 3 is arranged on the left and right sides in the middle of the whole, And vertically located directly below the two lifting rings 1; the steel frame 4 is arranged on the outside of the steel casing 3, and is welded with the steel frame 4; the water body 5 is arranged on the periphery of the whole; the silt area 6 is arranged on bottom of a body of water.

[0013] As an optimized technical solution of the present invention: after the steel casing 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com