Pile planting construction method for steel sheet piles

A construction method and steel sheet pile technology, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve problems such as difficulty in ensuring verticality control, insufficient static pressure, and influence of foundation strength, so as to improve the construction quality of pressed piles , noise and vibration are small, and the effect of reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The steel sheet pile pile construction method includes the following steps:

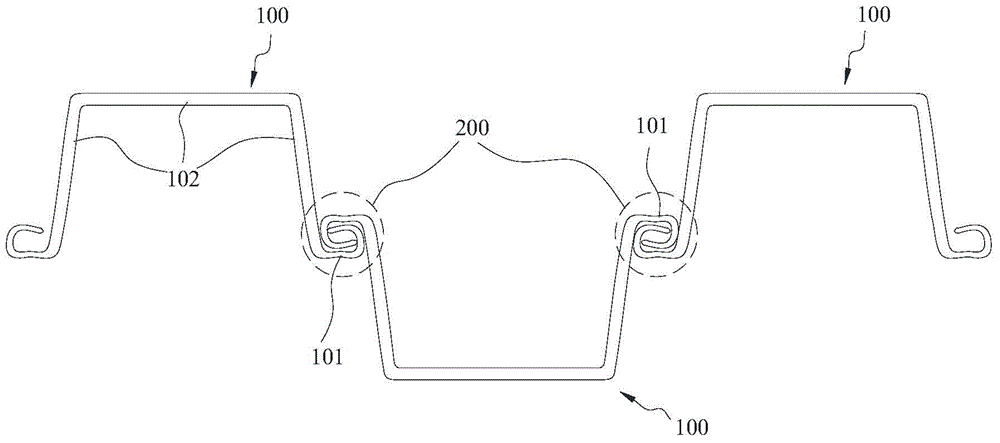

[0023] S1. Carry out pilot holes at positions corresponding to the locks 101 of the steel sheet piles 100 on the soil;

[0024] S2. A water jet is inserted into the tank body 102 of the steel sheet pile 100, and the nozzle of the water jet faces the soil for spraying high-pressure water;

[0025] S3. Align the buckle 101 of the steel sheet pile 100 with the guide hole, and continuously press a plurality of steel sheet piles 100 into the soil by static pressure, and monitor the verticality of each steel sheet pile 100 by using an infrared centering device .

[0026] The introduction hole step before the pile is adopted, that is, the introduction hole is made at the lock 101 of the steel sheet pile 100, so that the steel sheet pile 100 can be pressed into the hard soil layer more easily, without the overall correspondence with the steel sheet pile 100 on the soil lead hole at the position; usi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com