Underground anti-seepage construction method

A construction method and anti-seepage membrane technology, which is applied in infrastructure engineering, construction, etc., can solve problems such as unfavorable environmental protection and secondary pollution, and achieve the effects of cost saving, convenient grouting, and good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The underground anti-seepage construction method includes the steps of:

[0039] 1), such as figure 1 As shown, a groove 10 is hollowed out around the contaminated area, said hollow 10 surrounding the contaminated area.

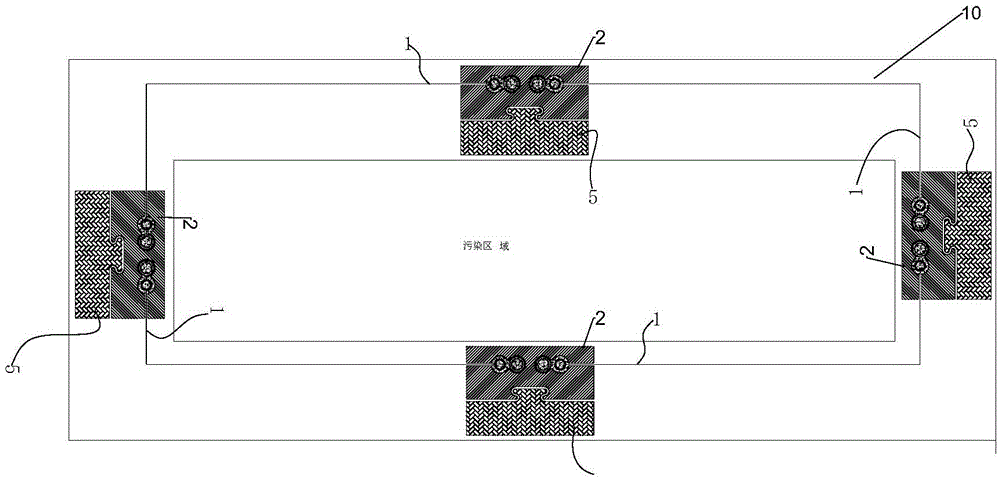

[0040] 2), such as figure 2 As shown, the underground anti-seepage device is lowered into the hollow tank 10. The underground anti-seepage device is connected as a closed ring.

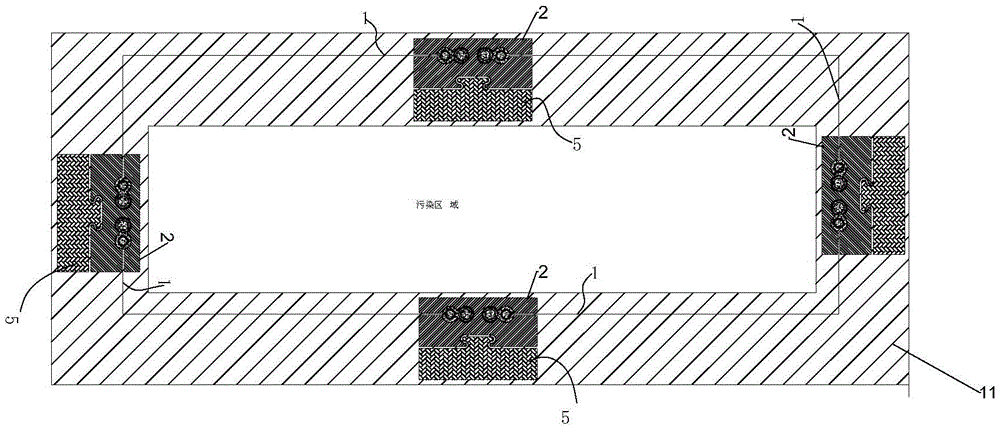

[0041] 3), such as image 3 As shown, sand 11 is used to backfill the hollow groove 10, and the underground anti-seepage device is fixed in the hollow groove 10.

[0042] Such as Figure 4 , Figure 5 As shown, the underground anti-seepage device includes a plurality of anti-seepage membranes or permeable membranes 1 and a plurality of connection joints for underground anti-seepage. The connection joint for underground seepage prevention includes a metal guide post 5 and a connection post 2 . The connecting post 2 has a dovetail groove 21 , and the metal guide post 5 ...

Embodiment 2

[0049] The underground anti-seepage construction method includes the steps of:

[0050] 1), such as figure 1 As shown, a groove 10 is hollowed out around the contaminated area, said hollow 10 surrounding the contaminated area.

[0051] 2) As described in Embodiment 1, lower the underground anti-seepage device into the hollow groove 10 . The underground anti-seepage device is connected as a seal

[0052]closed ring.

[0053] 3) As described in Embodiment 1, use sand 11 to backfill the hollow groove 10, and fix the underground anti-seepage device in the hollow groove 10.

[0054] Such as Figure 6 , Figure 7 As shown, the underground anti-seepage device includes a plurality of anti-seepage membranes or permeable membranes 1 , connecting columns 2 and metal guide columns 5 . The connecting post 2 has a dovetail groove 21 , and the metal guide post 5 is provided with a protruding head 51 . The protruding head 51 and the dovetail groove 21 engage with each other, so that th...

Embodiment 3

[0057] The underground anti-seepage construction method includes the steps of:

[0058] 1), such as figure 1 As shown, a groove 10 is hollowed out around the contaminated area, said hollow 10 surrounding the contaminated area.

[0059] 2) As described in Embodiments 1 and 2, lower the underground anti-seepage device into the cavity 10 . The underground anti-seepage device is connected to

[0060] closed loop.

[0061] 3), as described in Embodiment 1 and 2, use sand 11 to backfill the empty slot 10, and the underground anti-seepage device is fixed in the empty slot

[0062] within 10.

[0063] Such as Figure 8 , Figure 9 As shown, the underground anti-seepage device includes a plurality of anti-seepage membranes or permeable membranes 1 , connecting columns 2 and metal guide columns 5 . The connecting post 2 has a dovetail groove 21 , and the metal guide post 5 is provided with a protruding head 51 . The protruding head 51 and the dovetail groove 21 engage with each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com