Liquid-nitrogen natural-gas hydrate hole bottom freezing and rope coring drill bit

A rope coring and hydrate technology, which is applied in the direction of earth square drilling and extracting undisturbed core devices, etc., can solve the problems of complex structure of the sampler, low cooling efficiency, poor effect, etc., so that the sampling and freezing process can be easily realized, and the freezing High efficiency and the effect of improving the adoption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

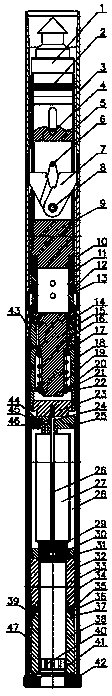

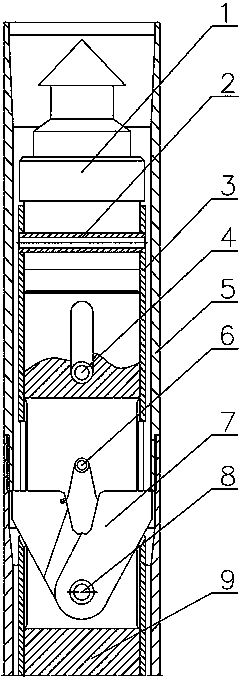

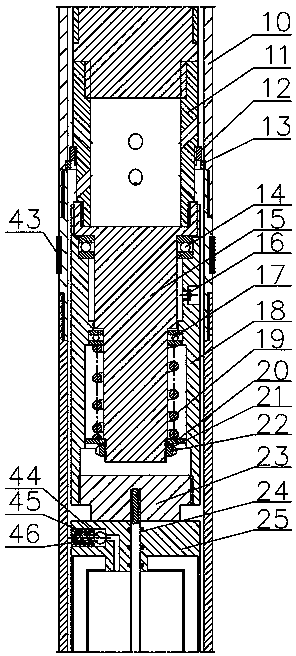

[0034] See figure 1 , figure 2 , image 3 with Figure 4 As shown, the present invention is composed of two parts: an inner tube assembly and an outer tube assembly. The inner tube assembly is composed of a spearhead 1, a first elastic pin 2 and a cartridge recovery tube 3. The spearhead 1 passes through the first elastic Pin 2 is hinged with cartridge recovery tube 3, and the salvaging mechanism realizes the process of putting the inner pipe assembly of the drilling tool into the hole and recovering through the connection of the salvage device and salvaging mechanism; at the same time, the core tube 34 is driven when the salvaging mechanism is lifted by the salvage device. Move upward to realize the process of pulling the inner tube.

[0035] The elastic card recovery tube 3 and the elastic card holder 9 are hinged by a second elastic pin 4, the connection between the second elastic pin 4 and the elastic card holder 9 is a movable connection, and the second elastic pin 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com