Long-rubber-barrel differential pressure type water filling packer capable of washing well

A pressure difference type, long rubber tube technology, applied in the direction of flushing wellbore, sealing/packing, wellbore/well parts, etc., can solve the problems of complex structure, setting seal, well washing impediment, etc., to achieve reasonable structural design, Highly functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

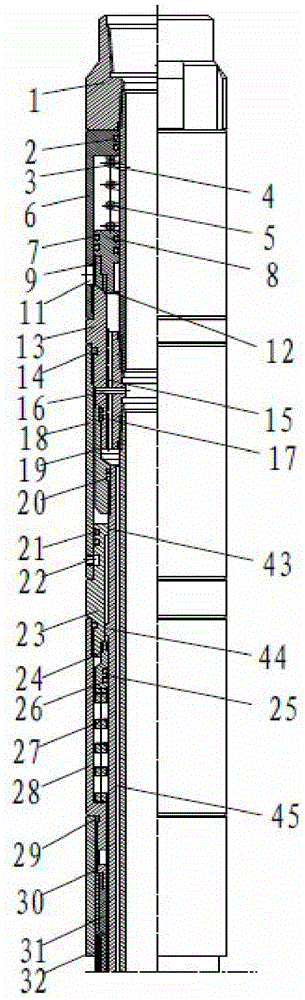

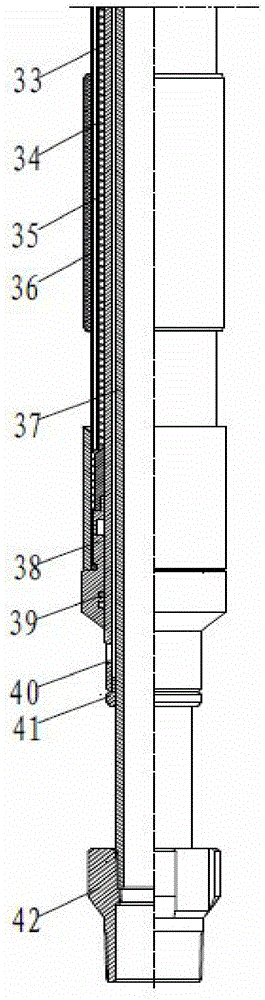

[0021] The well washable long rubber cylinder pressure differential water injection packer of the present invention includes a setting assembly, a rubber cylinder sealing assembly, a well cleaning assembly, and an unsealing device, which are connected with oil pipes to form an oil pipe string that is lowered into the casing of the wellbore. It is used for layered water injection in medium and deep wells with small card distance, thick oil layer and thin interlayer tubing, two-stage three-stage and above water injection wells.

[0022] See attached figure 1 , 2 . The upper joint 1, the upper central pipe 2, the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com