Automatic control method for synchronizer

A technology of synchronizer and pressure control, applied in transmission control, components with teeth, belt/chain/gear, etc., can solve the problem that the effect is not very good, the closed-loop synchronizer speed feedback of the synchronizer position is not considered, etc. Achieve the effect of improving shifting quality, optimizing power interruption time, and reducing synchronizer noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

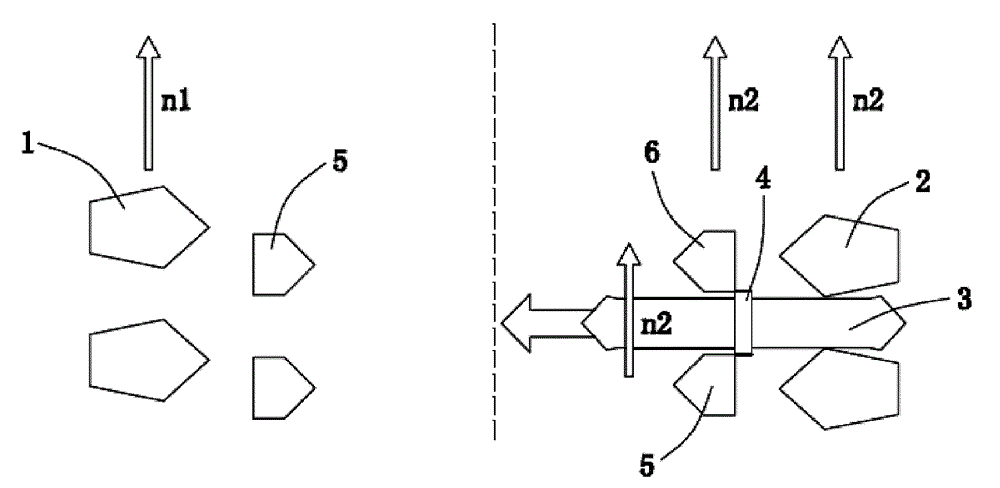

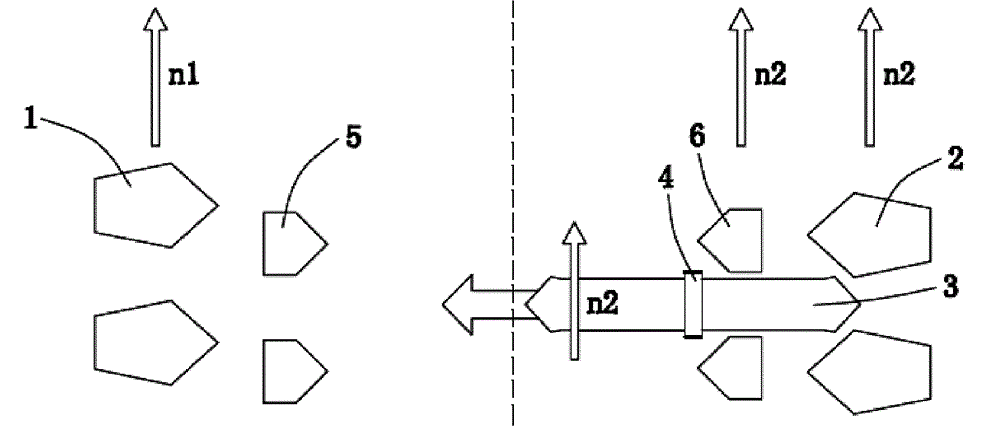

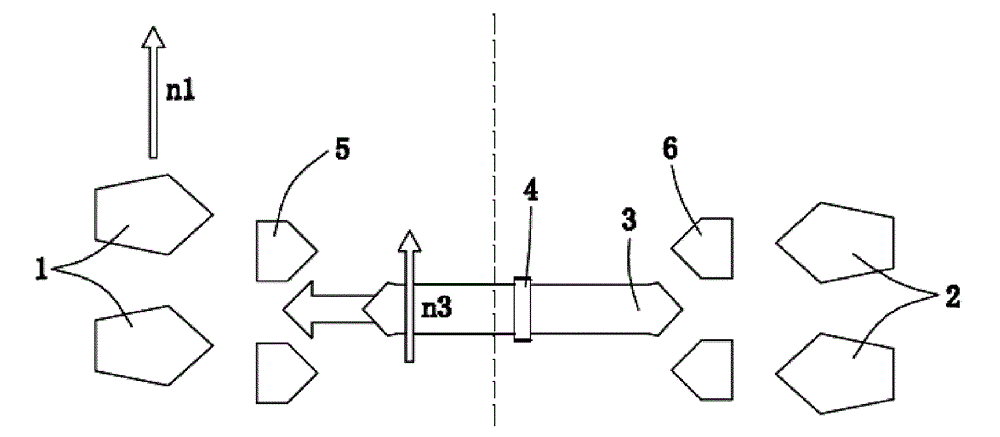

[0036] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0037] Fig. 1 shows a schematic diagram of an embodiment of an automatic control method for a synchronizer according to the present invention. As shown in Fig. 1, the step-by-step synchronizer automatic control method adopted by the present invention is as follows: TCU judges the shift command according to the synchronizer position signal, the vehicle demand gear signal, and the transmission oil pressure signal, and The speed and the time of each control stage divide the entire moving process into six controls: synchronizer unblocking, synchronizer front air stroke, synchronizer synchronous sliding, synchronizer rear air travel, synchronizer pressing, and synchronizer in gear. stage, combined with the accelerator pedal signal and transmission oil temperature signal to accurately control the speed control and position control of the synchronizer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com