An insert-type injection-molded pipe fitting and its production process

A technology of inserts and pipe fittings, which is applied in the direction of pipeline connection layout, pipes/pipe joints/pipe fittings, mechanical equipment, etc., which can solve the problems of difficult joint processing, poor pipeline sealing, and low pressure resistance, and achieve effective and stable connection and sealing Good sex and strong overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

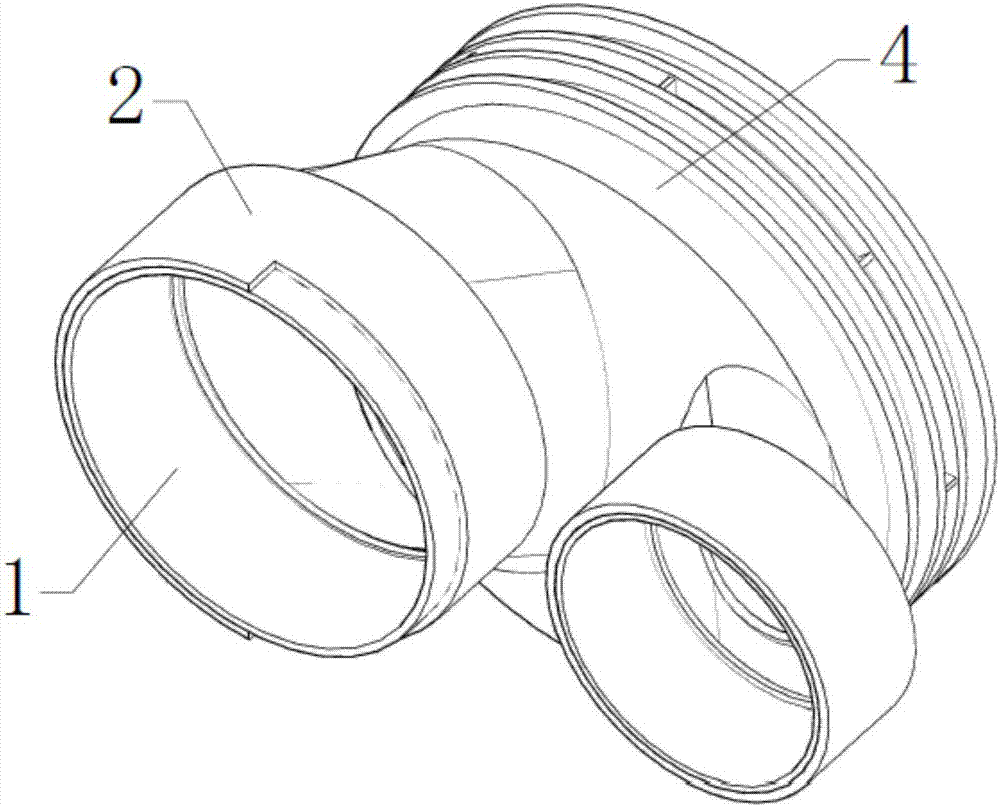

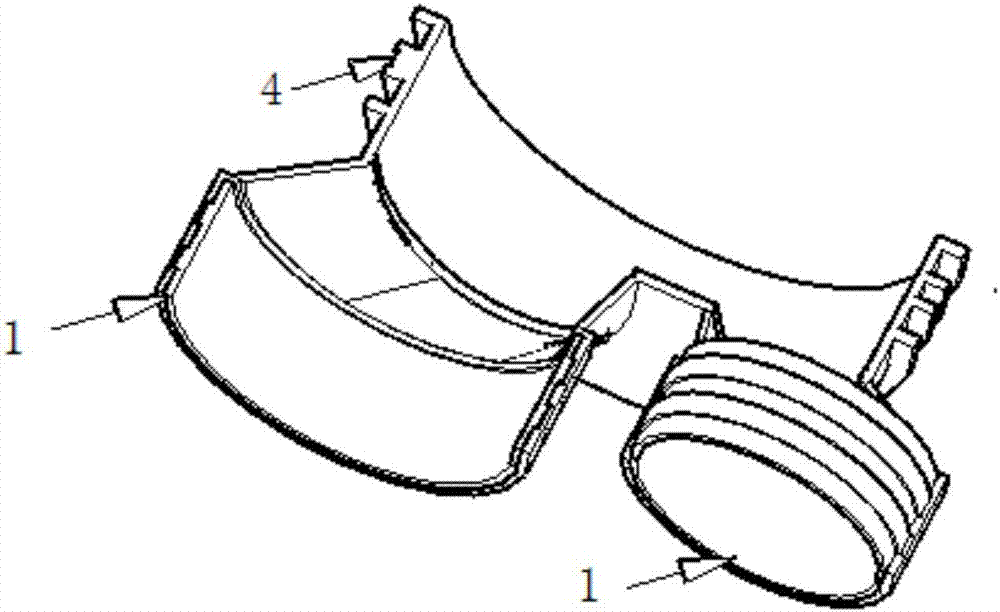

[0039] Such as Figure 1-2 shown.

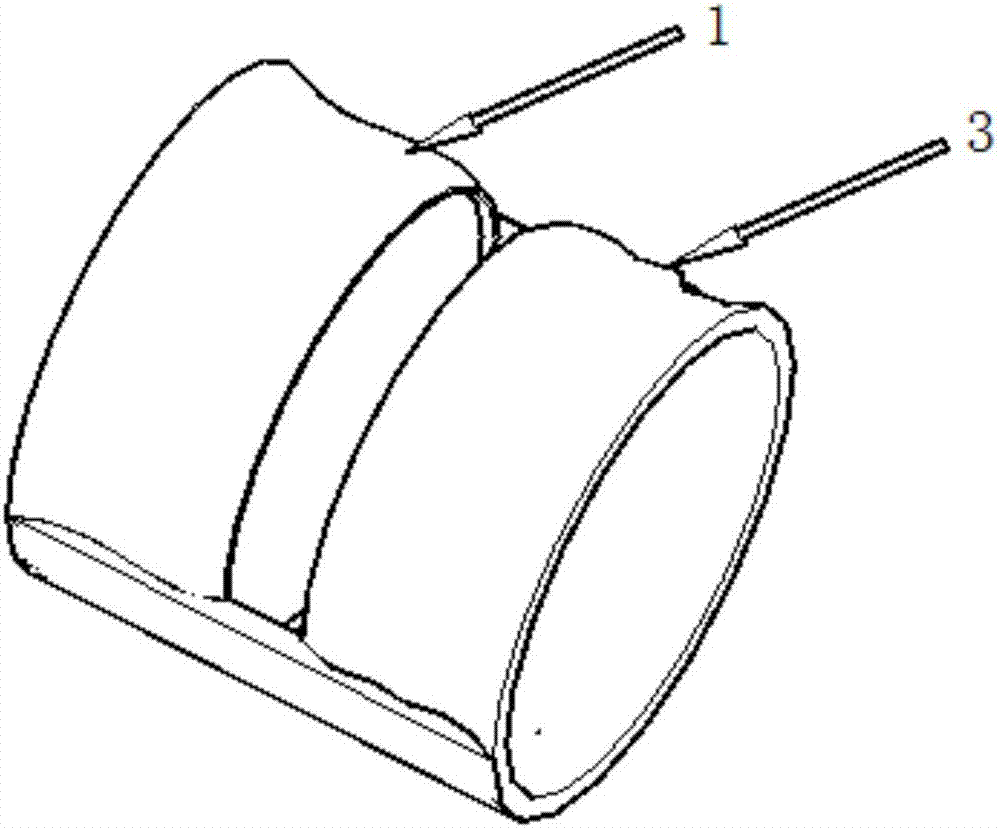

[0040] An insert-type injection-molded pipe fitting joint for a 250×160 / 110 confluence tee in an inspection well, comprising an insert 1 and a main body of the pipe, the insert 1 and the main body of the pipe are connected by injection molding; the main body of the pipe Including the joint part 4 and the joint part 2, the joint part 4 is airtightly and fixedly connected with the joint part 2; the insert 1 and the joint part 2 are socketed; the outer wall of the insert 1 is provided with three annular protrusions 3, the ring The protrusion 3 surrounds the outer surface of the insert 1 for a week; the inner wall of the connecting part 2 is provided with a groove corresponding to the shape of the annular protrusion 3, and the groove surrounds the inner wall of the connecting part 2 for a week; the annular protrusion 3 The insert is arranged in the groove; the material of the insert 1 is consistent with that of the pipe to be connected; the ins...

Embodiment 2

[0042] As described in Example 1, an insert-type injection-molded pipe fitting joint for a 250×160 / 110 confluence tee in an inspection well, the difference is that: the insert 1 is made of PVC / CPVC; the main part of the pipe fitting is Polyolefin material. PVC / CPVC pipes have high strength and can meet the strength requirements when the pipe wall is relatively thin; polyolefin has good fluidity and is easy to process.

Embodiment 3

[0044] As described in Example 1, a 250×160 / 110 fusion tee insert type PVC / CPVC pipe joint for inspection wells, the difference lies in: the corner of the raised part of the annular protrusion 3 and the protrusion The corners where the raised portion 3 contacts the outer side wall of the insert 1 are arc-shaped. The advantage of the design here is that not only the contact area between the insert 1 and the connecting part 2 is further increased, the connection is more stable, and the sealing and stability of the joint are further improved, but also the arc-shaped structure is conducive to the fluid flow inside the joint to prevent or Reduce the impact damage of the main material to the insert structure and prolong the service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com