Pre-drilling mechanism for combined firework pot combining machine

A combination of fireworks and pre-drilling technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of lower insertion success rate, insufficient pressing stroke, and obstruction of lead wire entry, etc., to improve processing quality and reduce processing time , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

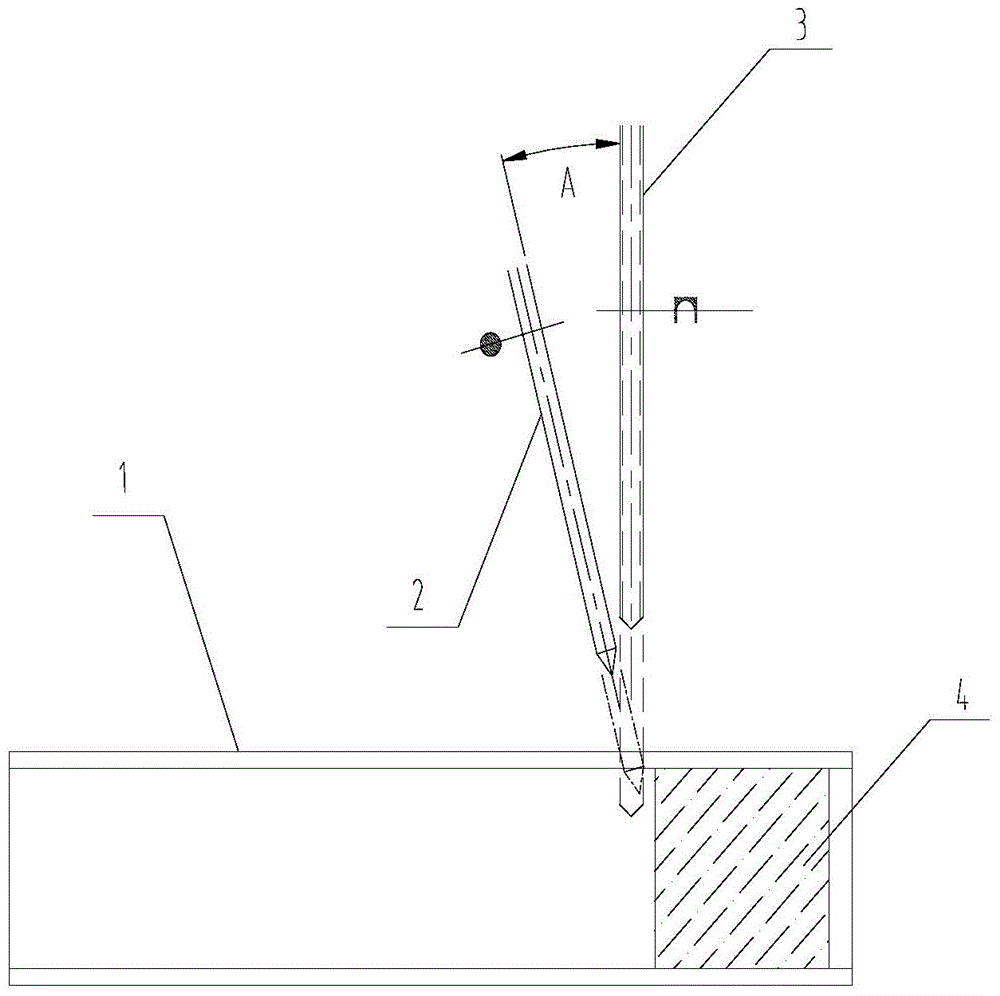

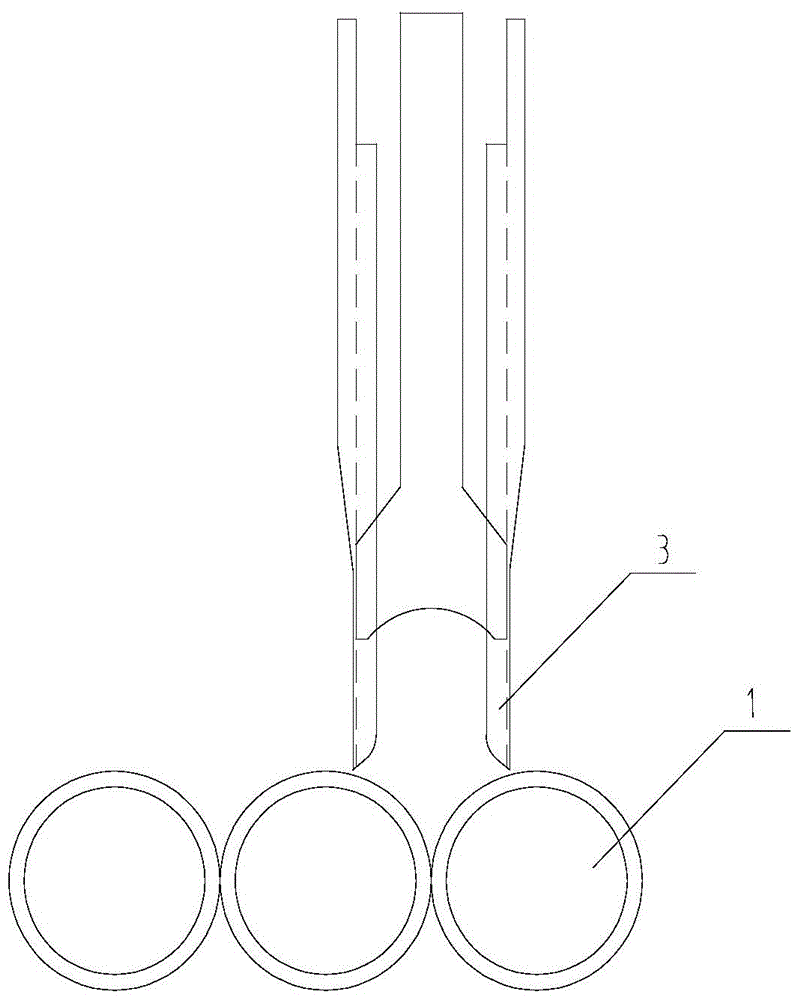

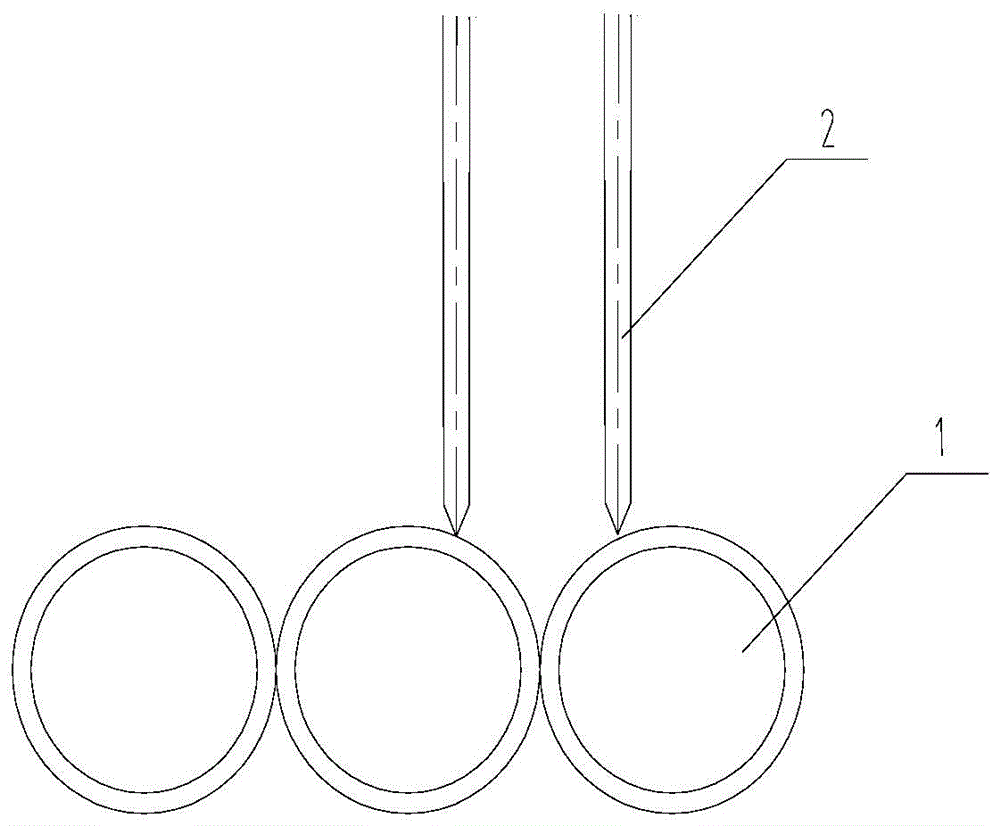

[0017] See attached Figure 1-3 , reflecting a specific structure of the present invention, the pre-drilling mechanism of the combined fireworks pot machine includes two parallel drilling needles 2, and the tails of the two drilling needles 2 are fixedly connected to the same linear reciprocating drive element ( not shown in the figure); the needle point of the drilling needle 2 faces the fireworks tube 1 to be processed, and the general punching or drilling position is selected above the inner mud layer 4 in the tube. The drilling needle 2 is composed of a conical needle point and a round bar-shaped needle shaft.

[0018] Under the working state of continuous introduction, the existing U-shaped needle 3 that completes the function of punching and inserting is perpendicular to the horizontal plane; the axial direction of the needle body of the drilling needle 2 and the vertical direction of the reference plane where the fireworks tube 1 to be processed are located have a clip....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com