A multi-shallow hole rock drilling medicine packing abutment

A technology for filling abutments and shallow holes, applied in blasting and other directions, can solve the problem of time-consuming, labor-intensive, and time-consuming problems of dispensing, and achieve the effects of improving work efficiency and personal safety, saving costs and time, and solving discontinuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

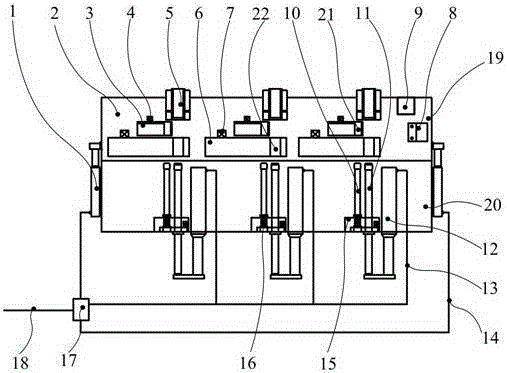

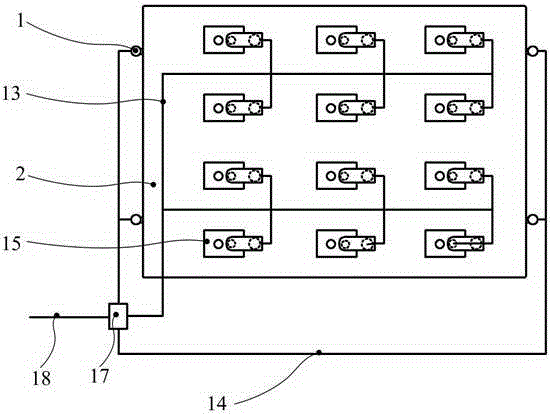

[0023] Specific embodiment 1: A multi-shallow hole rock drilling drug packaging filling platform, including a platform base frame 2 divided into a drug storage frame 19 and a drug filling frame 20, and at least one connection between the drug storage frame 19 and the drug filling frame 20 There are at least 12 groups of drug warehouse mechanisms installed in the drug warehouse rack 19, and the drug warehouse mechanisms include sequentially installed guiding blasting charges and a conduit 5 in the direction of the detonator, and a detonator supply driven by the detonator box motor 4. Cassette 3, the medicine bag supply box 6 driven by the medicine bag driving motor 7, the medicine filling frame 20 is provided with 12 groups of medicine filling mechanisms matching the medicine warehouse mechanism, and the medicine filling mechanism includes a control rod oil cylinder 12 Alternately driven drill pipe 11 and wooden push rod 10, shifting machine 15 for moving drill pipe 11 and woode...

specific Embodiment 2

[0028] Specific embodiment 2: except that the drilling depth is 20cm, and the drug storehouse mechanism and the medicine filling mechanism are 4 groups, all the other are the same as the specific embodiment 1.

specific Embodiment 3

[0029] Specific embodiment 3: except that the drilling depth is 150cm, and the drug storehouse mechanism and the medicine filling mechanism are 16 groups, and its arrangement mode is to be arranged in a circle, all the other are the same as the specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com