Two-dimensional fiber bundle micro vibration fiber sensor and using method thereof

An optical fiber sensor, two-dimensional optical fiber technology, applied in the direction of instruments, using wave/particle radiation, measuring devices, etc., can solve the problems of online detection, the influence of detection results, and the inability of the sensor probe to be charged, and achieve simple manufacturing and structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

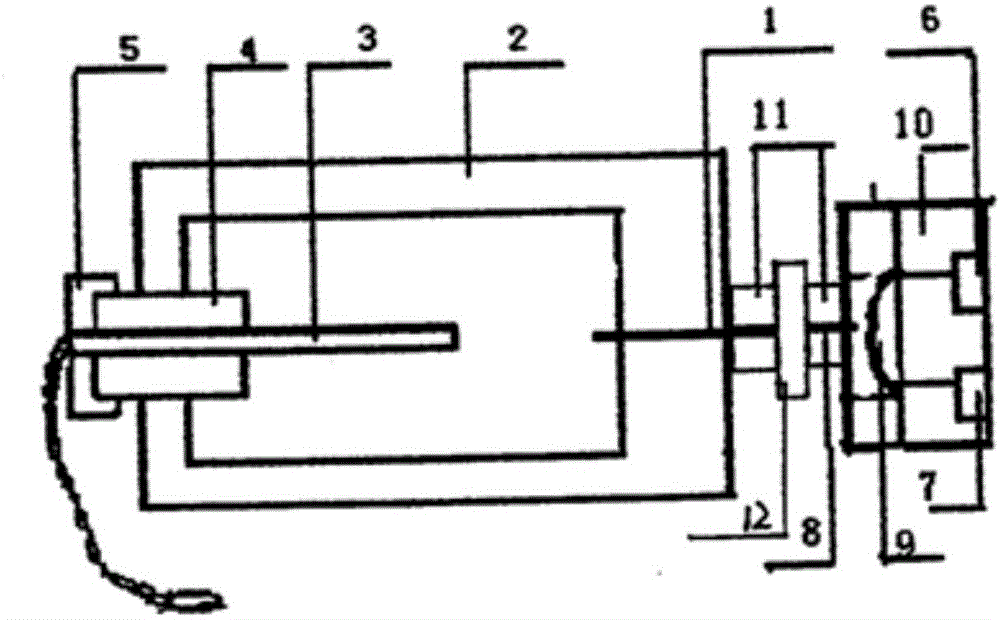

[0010] According to attached figure 1 : Take a large-core quartz optical fiber 3 with a diameter of 0.2 mm to 0.7 mm, fix it with an optical fiber fulcrum frame 4 at an appropriate position of the optical fiber 3, and then cure the optical fiber fulcrum frame 4 on one end of the cylindrical outer shell 2 with glue, and Fitted with the optical fiber connector 5, the other end of the outer shell 2 is assembled with the optical fiber bundle 1 through the first adapter 11, the light source is input from one end of the optical fiber connector 5, and the light is output through the optical fiber connector 5 → optical fiber 3 → first adapter 11; The image conversion device is made up of a second adapter 11', an image converter 9, a power interface 6 and an electrical signal output port 7. The optical image is input from the second adapter 11', and the optical image of the optical fiber bundle 1 is converted into an image by the image converter 9. Electrical signal output. The light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com