Cogging-torque test method for alternating-current permanent-magnet synchronous servo motor

A servo motor, cogging torque technology, applied in torque measurement, measurement device, power measurement and other directions, can solve the problems of low precision and large error, and achieve the effect of simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for testing the cogging torque of an AC permanent magnet synchronous servo motor, the specific measurement method is as follows:

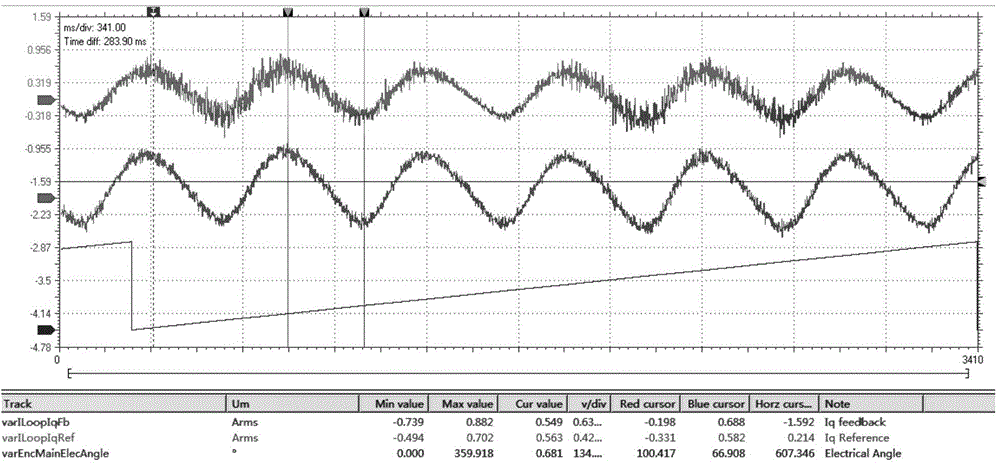

[0020] 1. First connect the motor under test, driver and encoder, and then zero-adjust the encoder. 2. Test the back electromotive force of the motor and calculate the current torque constant Kt. 3. Set the relevant control parameters of the driver, rotate the motor, and continuously adjust the parameters so that the motor can run stably at no-load and low speed. 4. Set the speed of the motor under test to a lower speed of 1 to 5 rpm. 5. Use the analog oscilloscope module that comes with the driver software to collect the electrical angle and feedback current waveform of the motor in real time. 6. By analyzing and calculating the current waveforms in multiple electrical cycles, the cogging torque is obtained.

[0021] Such as figure 1 As shown, the abscissa is time, and the waveforms of the ordinate are electrical angle, referen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com