A Fault Diagnosis Method for Rolling Bearings Based on Multidimensional Vibration Feature Fusion in Time-Frequency Domain

A rolling bearing and fault diagnosis technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems that the time domain characteristics cannot reflect the vibration information in the frequency domain, cannot reflect the trend of the time domain characteristics, and the signal characteristics are not comprehensive, so as to reduce feature redundancy, Improve the calculation time complexity and improve the effect of diagnosis efficiency

Active Publication Date: 2017-09-15

BEIJING JIAOTONG UNIV +1

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The signal characteristics reflected by a single time domain feature and frequency domain feature are not comprehensive, the time domain feature cannot reflect the vibration information in the frequency domain, and the characteristic trend of the time domain cannot be reflected in the frequency domain analysis.

In the past fault diagnosis, the features of a single domain were extracted, or a small number of typical features were extracted for diagnostic analysis, and the diagnostic accuracy was limited. This urgently requires a more comprehensive diagnostic algorithm to achieve a breakthrough in diagnostic accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

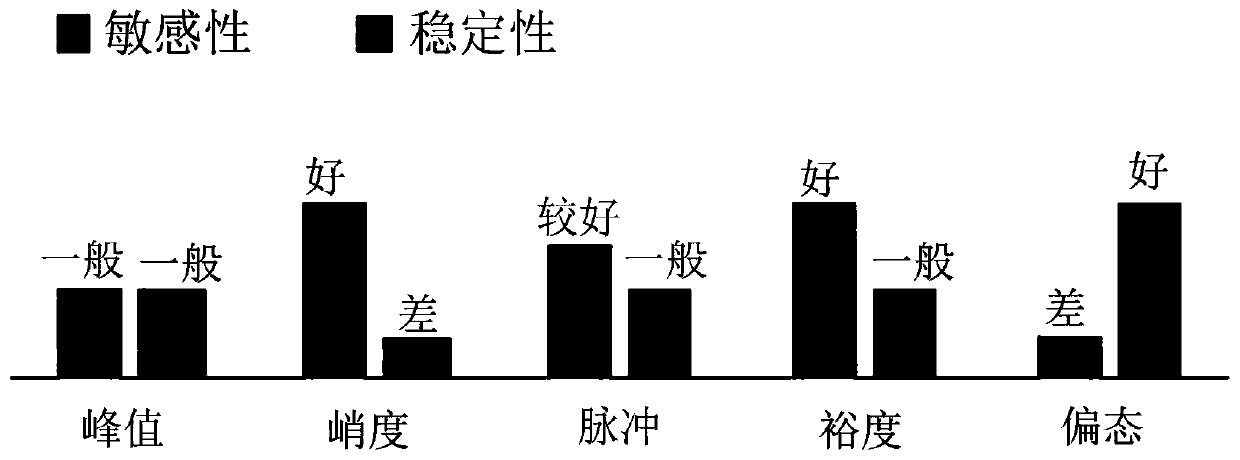

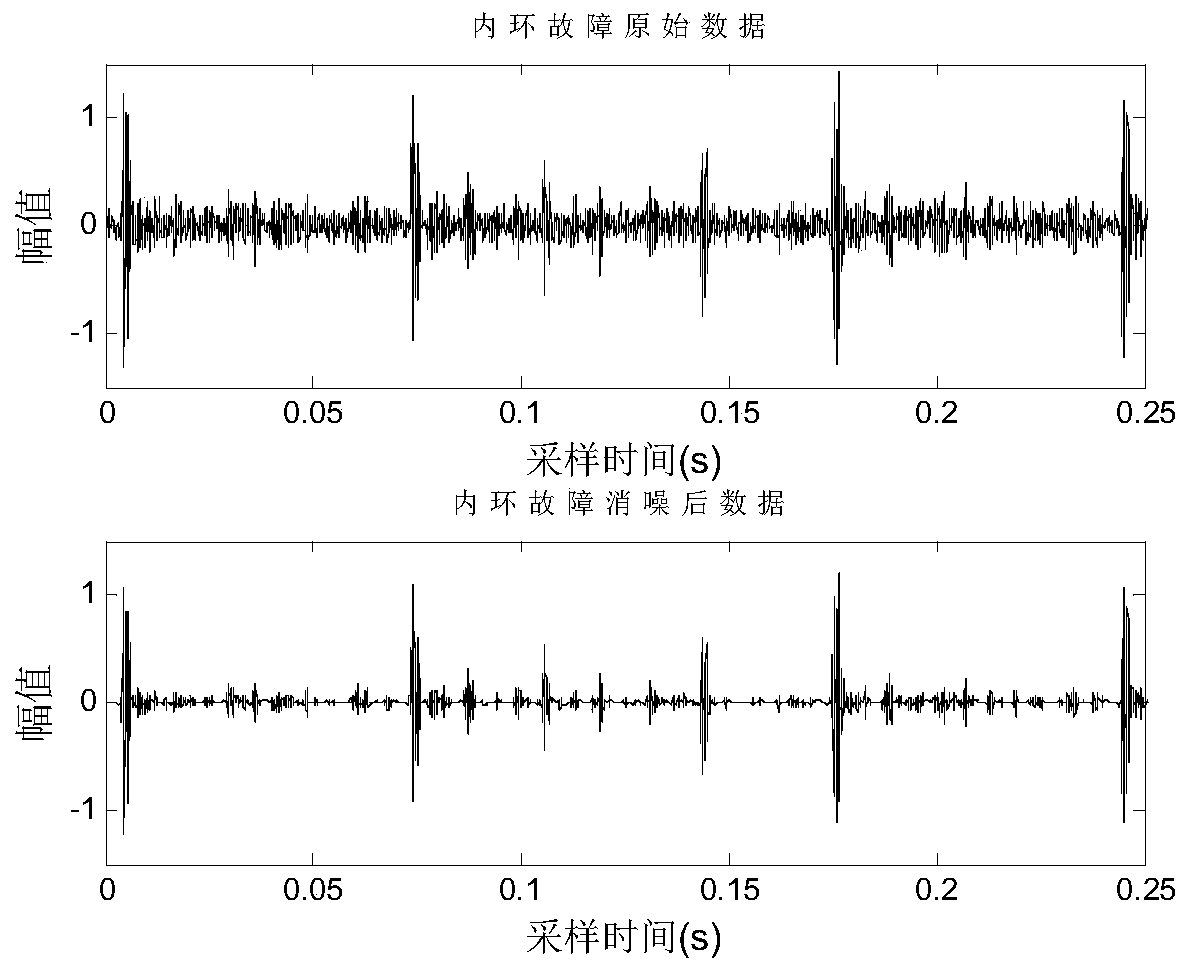

The present invention proposes a rolling bearing fault diagnosis algorithm based on multi-dimensional fault feature fusion in the time-frequency domain, aiming at the vibration signals in the four states of normal state, roller fault, inner ring fault and outer ring fault of the rolling bearing in the time-frequency domain respectively The characteristics of faults are extracted by extracting time-domain and frequency-domain features, removing redundancy, and re-integrating ideas to optimize the description of fault characteristics and obtain intelligent discrimination results. First, perform wavelet denoising on the extracted original rolling bearing vibration data, then extract time-domain feature vectors to form a time-domain feature matrix, and extract wavelet packet decomposition and reconstructed coefficient energy moments to form a frequency-domain feature matrix, and further fuse the time-frequency domain matrix , to obtain the multi-dimensional fault feature matrix in the time-frequency domain. Perform de-redundancy processing on the multi-dimensional feature matrix to obtain a new multi-dimensional feature matrix. Then, the multi-dimensional features are fused with the weighted feature index distance, and the state discrimination result of the rolling bearing is obtained through the fused feature index distance.

Description

A Fault Diagnosis Method for Rolling Bearings Based on Multidimensional Vibration Feature Fusion in Time-Frequency Domain technical field The invention belongs to the field of automatic detection and pattern recognition, and in particular relates to fault diagnosis and intelligent recognition methods of rotating machinery. Background technique The fault diagnosis of rolling bearings probably started in the 1960s. After decades of rapid development, it has now become a comprehensive applied discipline that combines the fields of mechanical detection, automatic control and pattern recognition. As a key component in mechanical equipment, rolling bearings play a vital role in the normal operation of the mechanical system. There are many factors that affect the running state of rolling bearings, such as temperature, mechanical and environmental factors. Some failures are instantaneous, while others are caused by slow and long-term degradation. The resulting rolling bearing fai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M13/04

Inventor 付云骁贾利民吕劲松季常煦姚德臣李乾卢勇

Owner BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com