Rolling bearing fault diagnosis method based on time-frequency domain multidimensional vibration feature fusion

A rolling bearing and fault diagnosis technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems that the time domain characteristics cannot reflect the vibration information in the frequency domain, cannot reflect the trend of the time domain characteristics, and the signal characteristics are not comprehensive, so as to reduce feature redundancy, The effect of improving the computational time complexity and improving the efficiency of diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

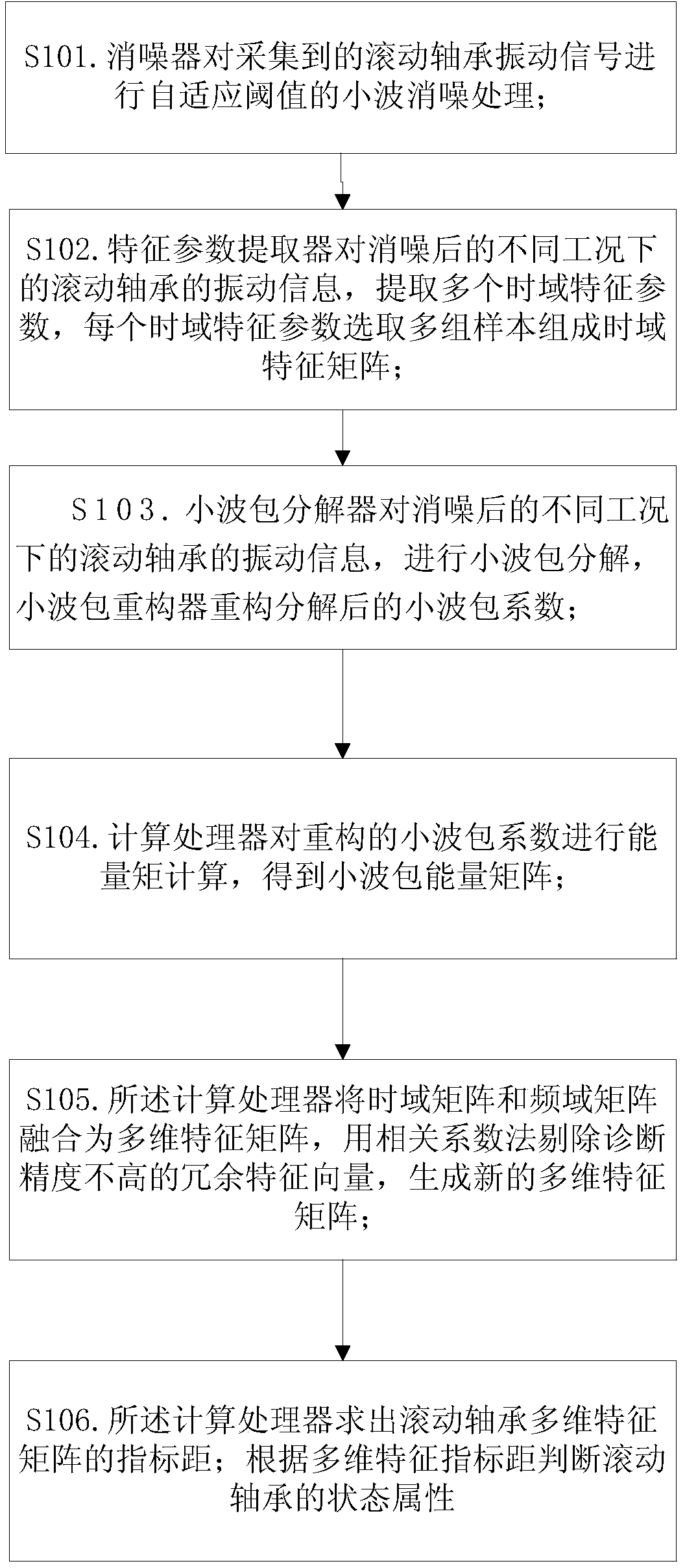

[0022] The flow chart of the rolling bearing fault diagnosis method based on multiple characteristic parameters proposed by the present invention is as follows figure 1 Shown:

[0023] S101. The denoiser performs adaptive threshold wavelet denoising processing on the collected vibration signal of the rolling bearing;

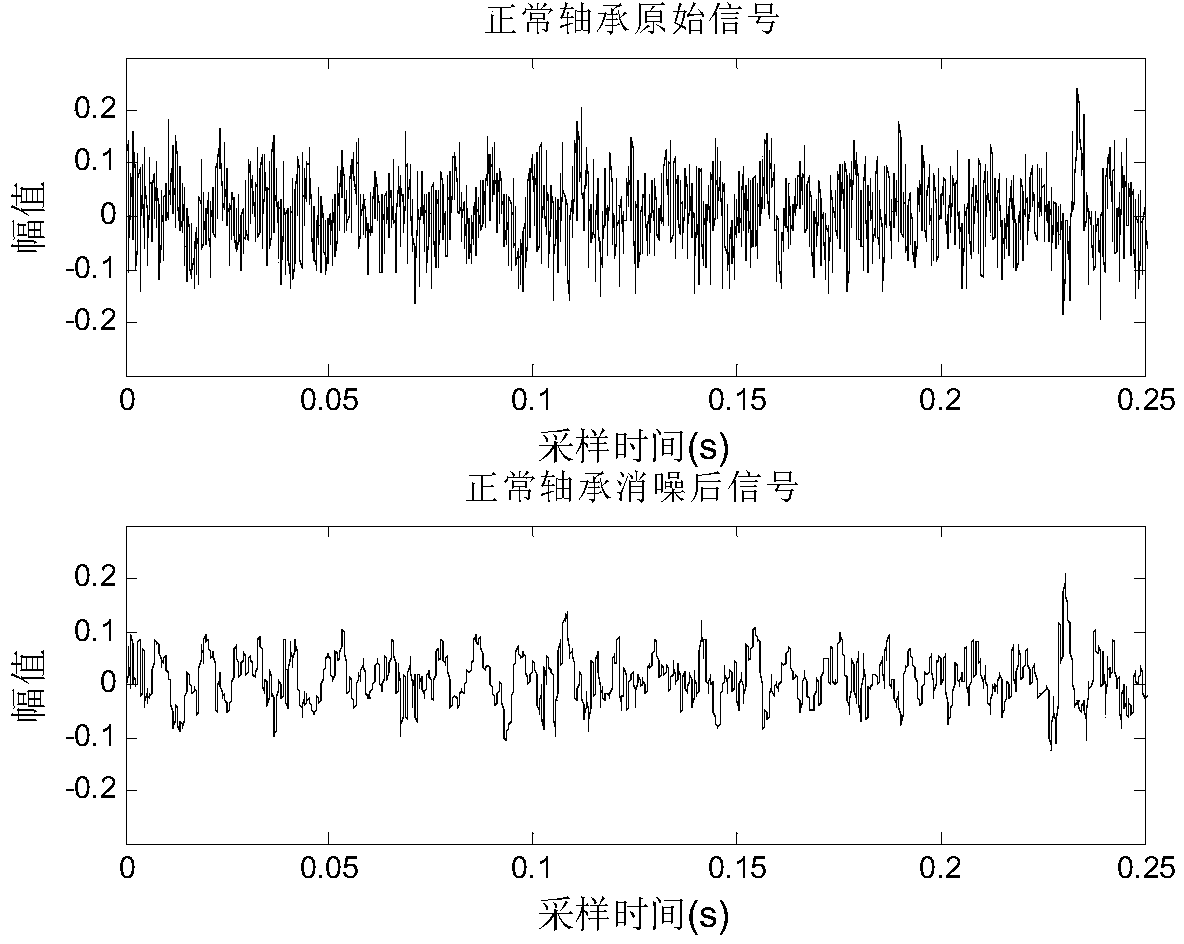

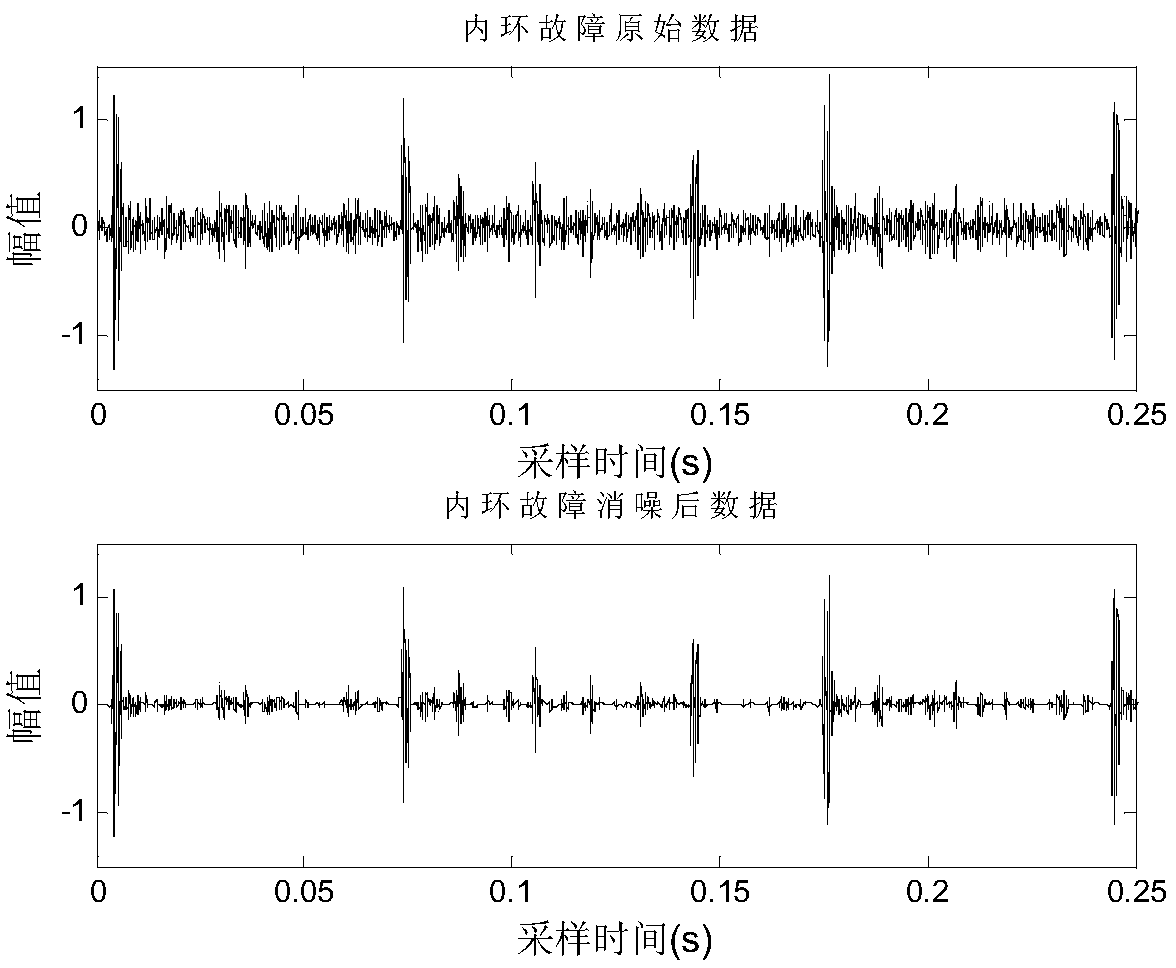

[0024] The denoiser performs adaptive threshold wavelet denoising processing on the collected original rolling bearing vibration signals. Rolling bearings are often affected by the vibration of nearby equipment and other external factors during operation. In practical applications, the noise canceller needs to denoise the signal and remove interference information to ensure that the fault diagnosis of rolling bearings is true and reliable. Denoising is carried out by wavelet adaptive threshold method, and the binary wavelet transform coefficient ω is firstly calculated by the following formula j,k Perform compression to obtain the wavelet coefficient α after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com