Device and method for measuring yarn bending rigidity

A bending stiffness and measuring device technology, applied in the direction of using a stable bending force to test the strength of materials, etc., can solve the problems of difficult test operation, difficult implementation, large errors, etc., to avoid yarn twisting, reduce measurement errors, and characterization methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

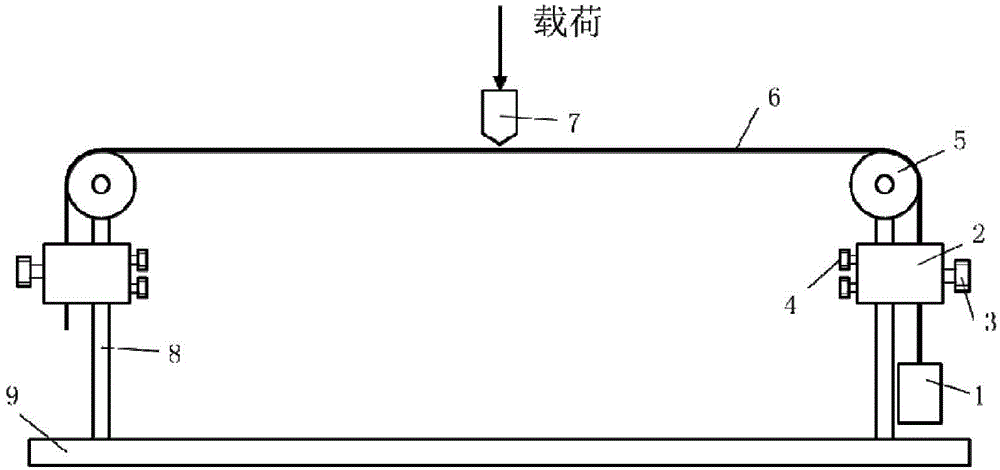

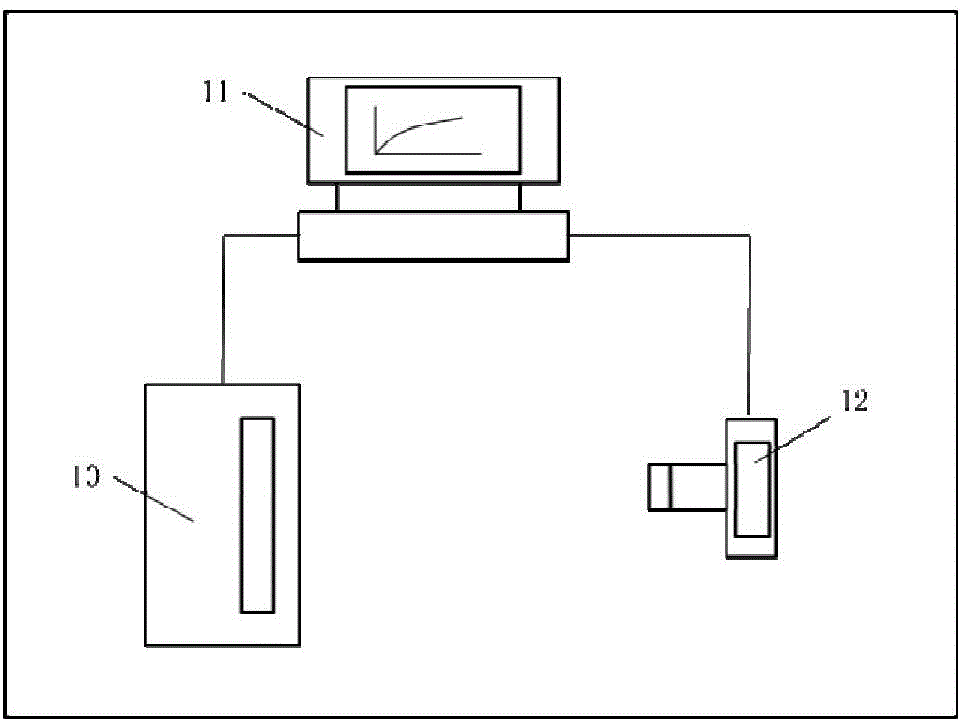

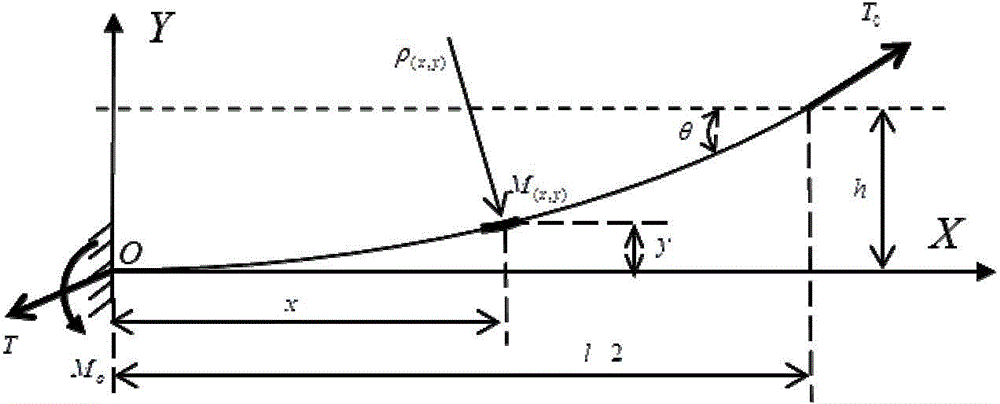

[0037] The invention provides a yarn three-point bending experimental device, such as figure 1 As shown, the experimental device consists of a mass 1, a yarn clamp 2, a fixed pulley 5, a yarn 6, an indenter 7, a support 8, a base 9, a uniaxial tensile testing machine 10, a computer controller 11 and a CCD camera 12 constitute. in:

[0038] A base 9 is fixed on the base of the uniaxial tensile testing machine 10;

[0039] A bracket 8 is respectively fixed at the left and right ends of the base 9;

[0040] The upper end of the bracket 8 is equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com