Ultrasonic phased array probe system used in transversal flaw detection in tubular material or rod material

A technology of ultrasonic phased array and phased array probe, which is applied in the direction of material analysis, measuring device, and material analysis using sound wave/ultrasonic wave/infrasonic wave, which can solve the problem of reducing the signal-to-noise ratio of transverse wound detection, missed detection, and acoustic echo Low energy and other issues, to avoid energy loss, eliminate energy loss, improve the effect of signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

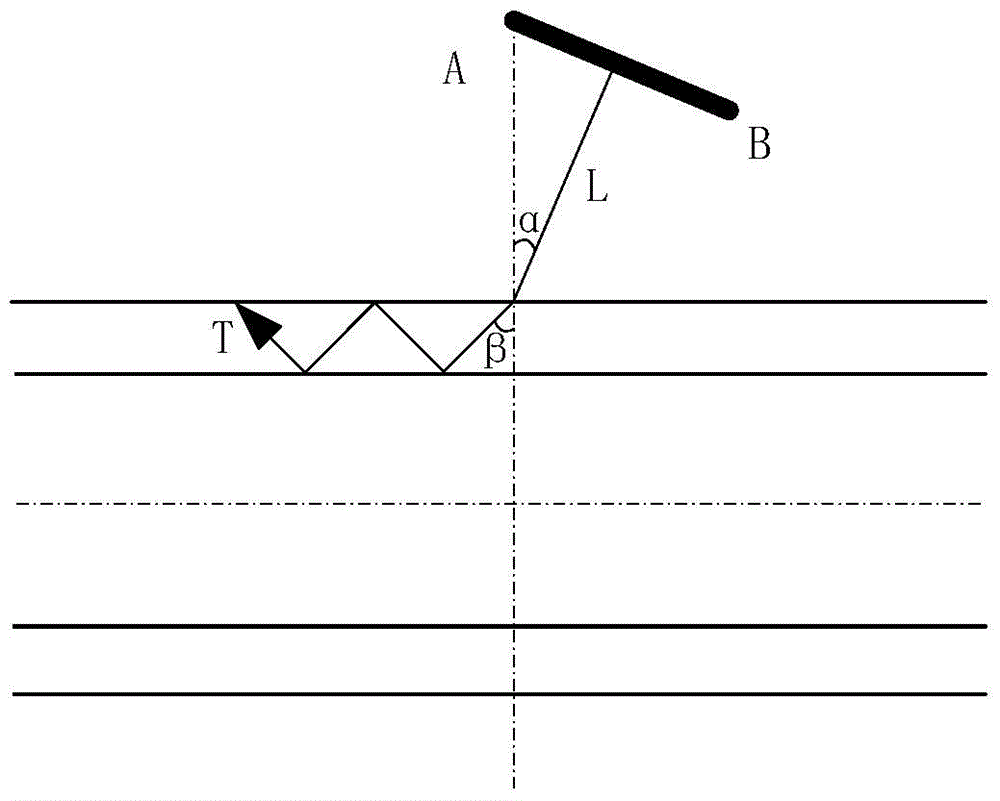

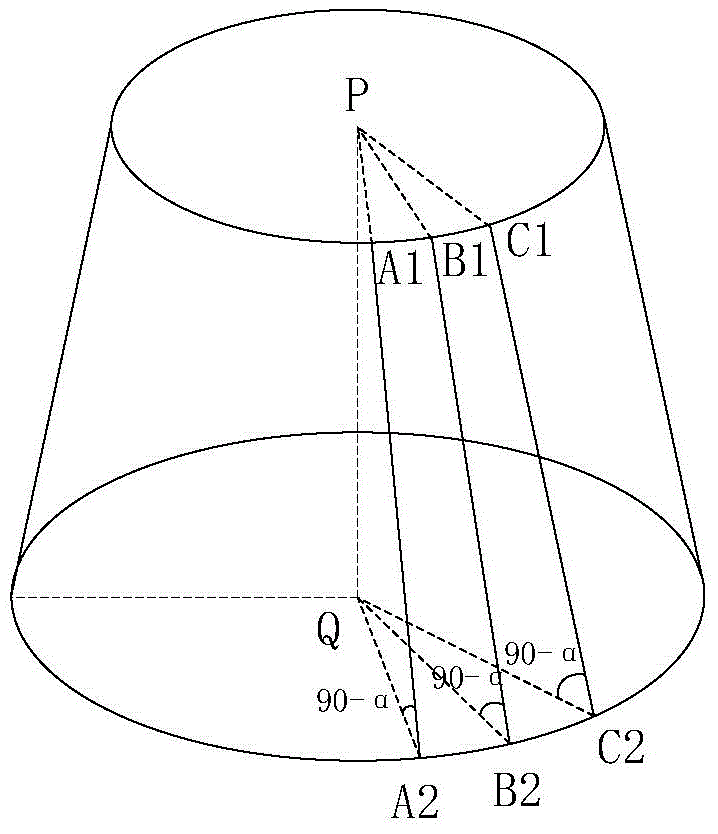

Method used

Image

Examples

Embodiment 1

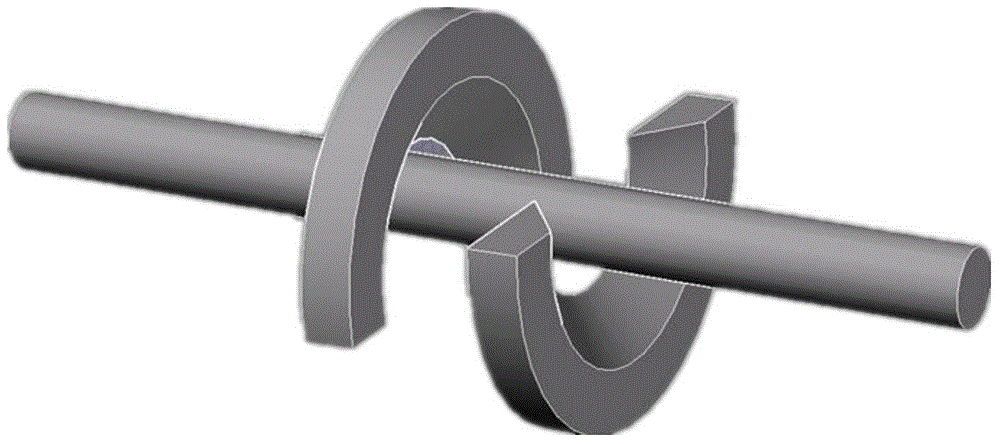

[0025] In the above-mentioned phased array probe, the probe chips are evenly distributed on the side of a circular platform around the pipe or rod, that is, all the chips in the probe are evenly distributed in the circumferential direction of the pipe or rod, covering a 360-degree scanning range. However, in the actual manufacturing process of the phased array probe, it is difficult to manufacture a complete frustum of a cone due to technical difficulties. For this reason, the phased array probe can be made into two phased array probes, and each phased array probe is a semi-circular table structure. For scanning detection, using two such semi-circular table structures can realize 360-degree full-range scanning detection of pipes or bars, see image 3 . In order to eliminate the scanning blind area between the probes of each semi-circular table, each semi-circular table should be made to have a scanning range slightly larger than 180 degrees, that is, the central angle formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com