High-efficiency cycloidal-pin wheel speed reducer with sensor

A pin-wheel reducer and sensor technology, applied to components with teeth, belts/chains/gears, transmission boxes, etc., can solve the problems of reducing transmission efficiency and improving reducers, so as to eliminate energy loss and high reliability , The effect of high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

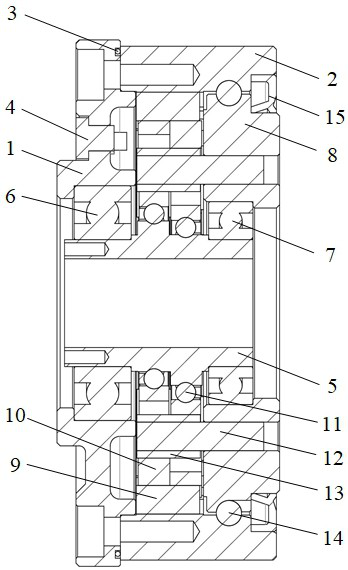

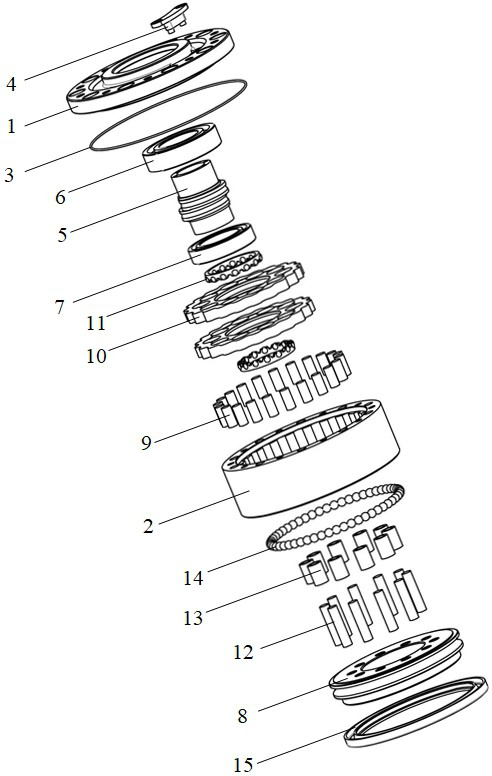

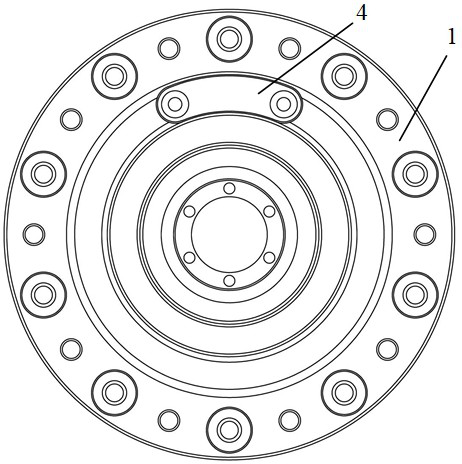

[0018] like Figure 1-Figure 4 As shown, this specific embodiment adopts the following technical scheme: it includes a support end 1, a pin gear housing 2, a sealing ring 3, a sensor 4, a crankshaft 5, a first standard ball bearing 6, a second standard ball bearing 7, an output End 8, needle roller 9, cycloid wheel 10, first non-standard ball bearing 11, cylindrical pin 12, column pin sleeve 13, second non-standard ball bearing 14, rotating skeleton oil seal 15. Wherein the support end 1 is fixedly connected with the pin gear housing 2 and a sealing ring 3 is installed on the connection surface, a sensor 4 is installed on the support end 1, and the two ends of the crankshaft 5 are respectively supported by a first standard ball bearing 6 and a second standard ball bearing 7 Supported on the support end 1 and the output end 8, a number of needle rollers 9 are placed in the pin gear housing 2, and the two cycloidal wheels 10 are respectively supported on the eccentric shaft sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com