Method for predicting machining quality of machine tool

A prediction method and machine tool technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as cost expenditure and reduction of tool machine utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

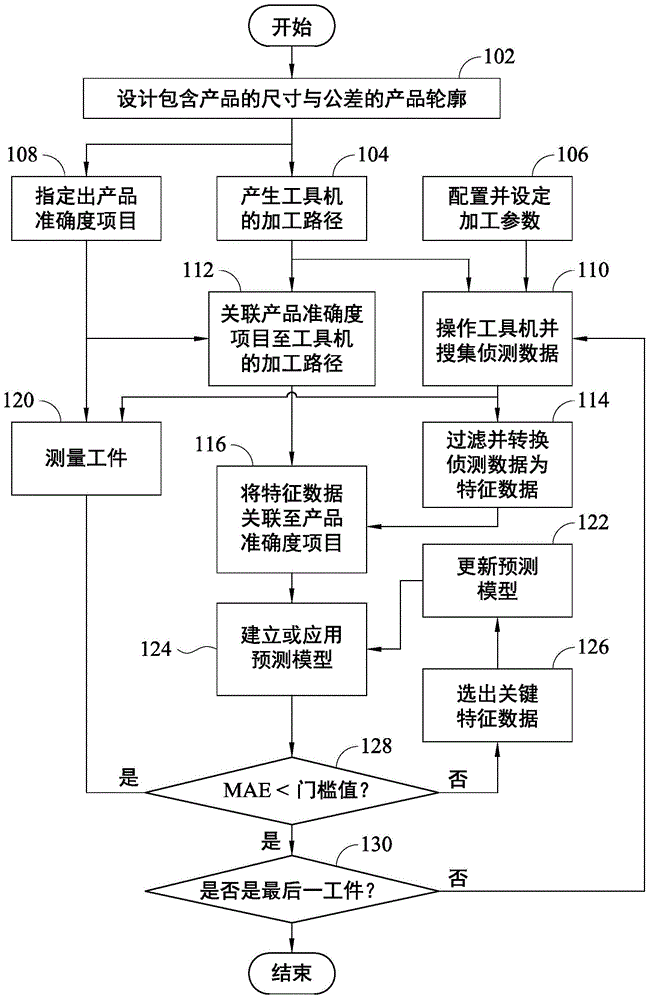

Method used

Image

Examples

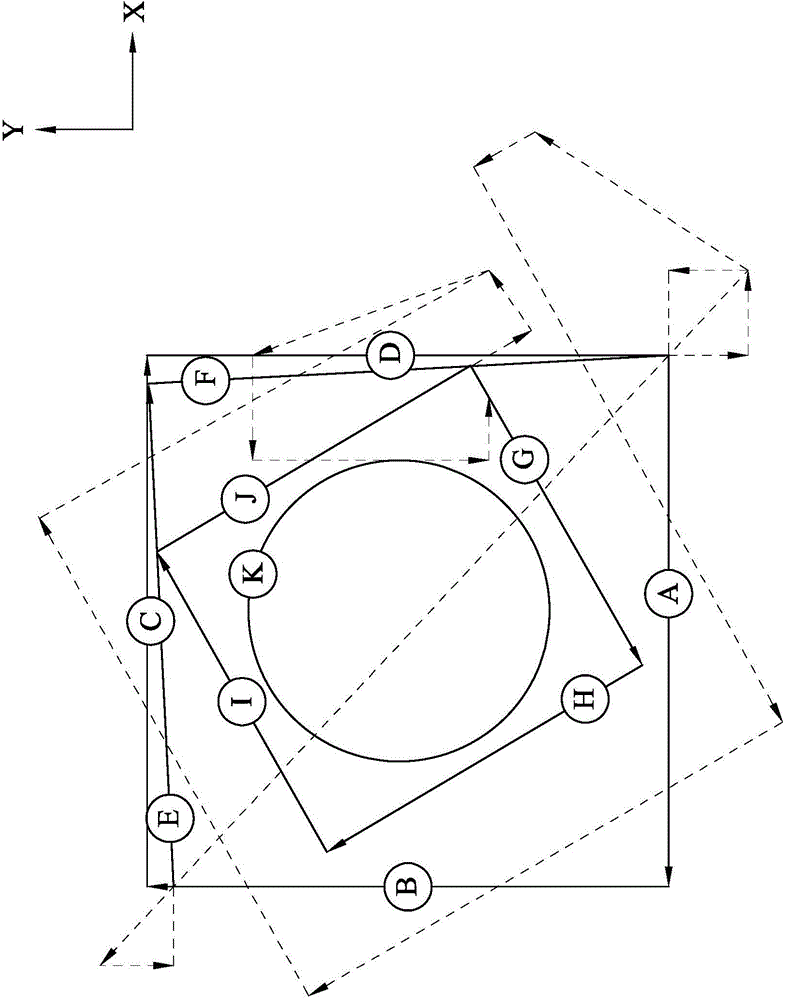

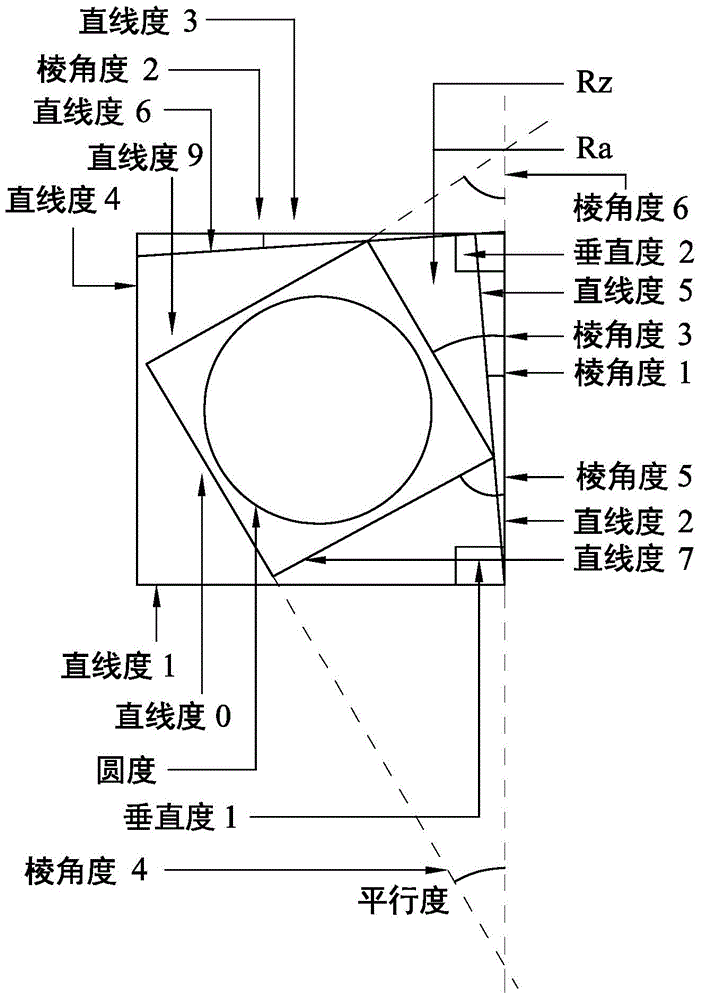

Embodiment Construction

[0020] In the high-tech industry, virtual measurement has become an effective way to measure workpieces. For example, in the thin film transistor-liquid crystal display (TFT-LCD) and semiconductor industries, wafers and glass are respectively thin film transistor-liquid crystal display and semiconductor Artifacts in industry. The basic preparation for virtual metrology on a process is to build a predictive model, a virtual metrology model, that closely models the input-output of the process. A virtual measurement model can be generated by training some calculus methods (such as backpropagation neural network and multiple regression technology), and use historical process parameters as input and corresponding workpiece manufacturing quality data as output. Once the process parameter data of a workpiece is input, the virtual measurement model immediately estimates the manufacturing quality of the workpiece, so as to detect abnormalities in equipment or process in time. For the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com