Automatic rocket tank structure three-dimensional model constructing system

A technology of three-dimensional models and storage tanks, which is applied in 3D modeling, image data processing, special data processing applications, etc., can solve the problems of uneven design model quality, many repetitive tasks, and low design standardization, and achieve improved Work efficiency and product quality, reduce the probability of missing errors, and improve the effect of design quality level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further introduced below in conjunction with the accompanying drawings.

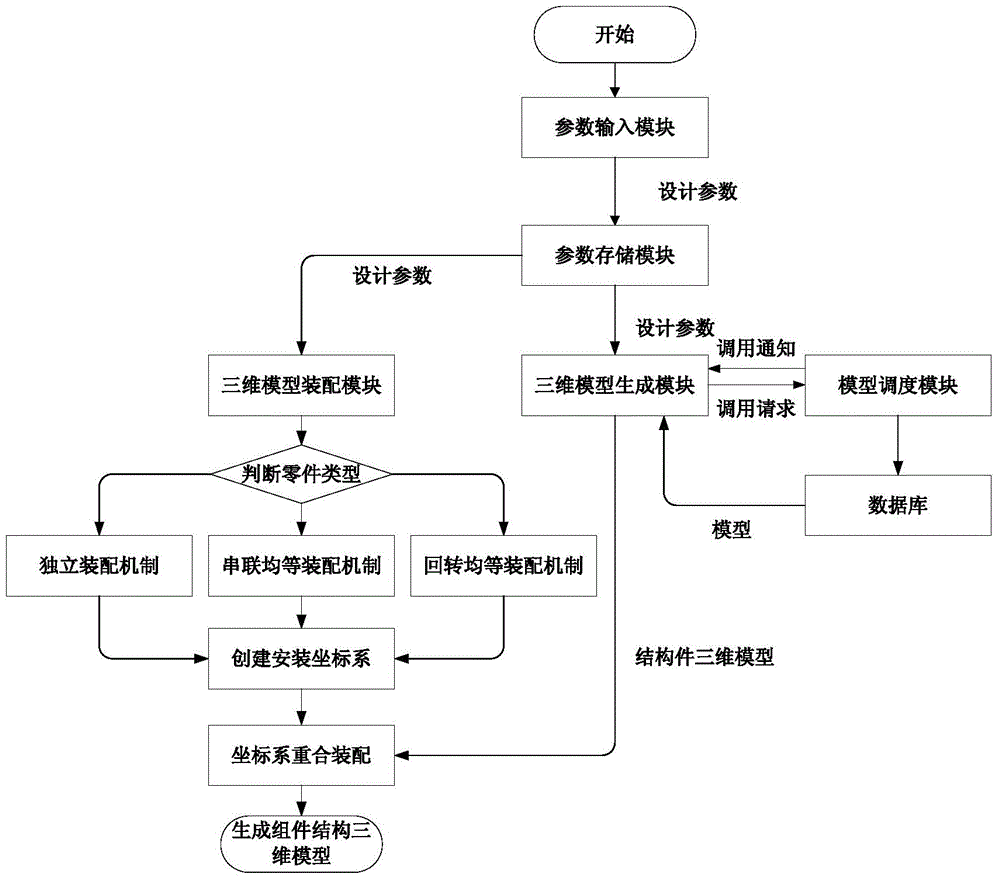

[0025] Such as figure 1 As shown, a system for automatically building a three-dimensional model of a rocket tank structure in the present invention includes: a database, a parameter input module, a parameter storage module, a model scheduling module, a three-dimensional model generation module and a three-dimensional model assembly module;

[0026] The database is used to store the three-dimensional model of the structural parts required for the construction of the rocket tank; the three-dimensional model of the structural parts includes the wall panels, short shell plates, melon petals, end frames, flanges, anti-shake plates, and clamps of the tank , tunnel pipe, chemical milling panel and Y-ring;

[0027] The parameter input module receives the design parameters input by the user, and sends the design parameters to the paramet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com