Milling stability predicting method based on cubic polynomial

A stability prediction, polynomial technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low computational efficiency of calculation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

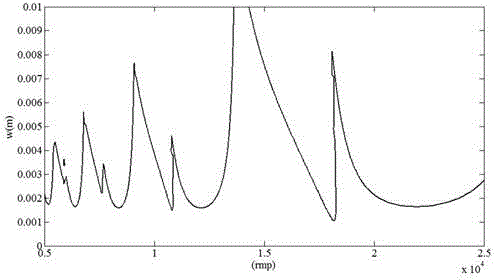

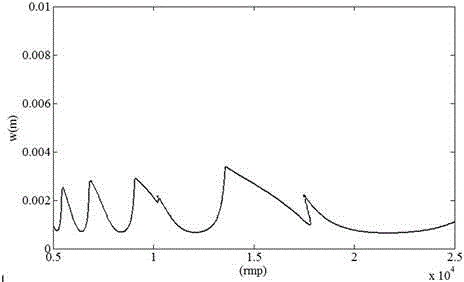

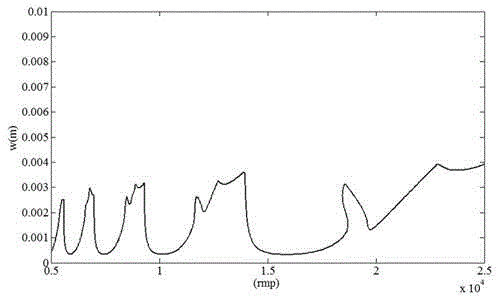

Image

Examples

Embodiment Construction

[0155] this invention Implement with the following steps:

[0156] ① Establish the dynamic equation of the milling cutter in the single-degree-of-freedom milling process:

[0157] (1)

[0158] in, is a constant coefficient matrix, is the coefficient matrix that changes with time period,

[0159] Indicates that the tool is momentary status response, Indicates the natural frequency of the tip point, represents the relative damping, represents the modal mass, is the axial depth of cut, Indicates time lag;

[0160] Indicates the instantaneous chip thickness, and its expression is:

[0161] (2)

[0162] In formula (2), Indicates the number of teeth of the milling cutter, and are the cutting force coefficients in the tangential and normal directions, respectively, for the first The angular displacement of the cutter tooth, the expression is , the window function The definition formula is:

[0163] (3)

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com