Full-color point control type video photoelectric glass and processing method thereof

A technology of photoelectric glass and processing method, which is applied in the directions of instruments, identification devices, static indicators, etc., can solve the problems of inconspicuous video effects, unsatisfactory video effects, and invisible LED modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

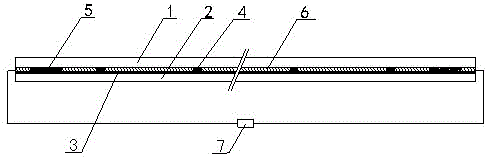

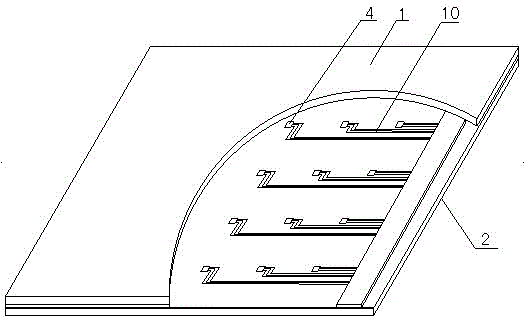

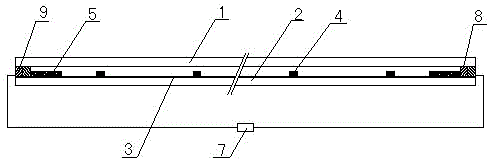

[0034] Such as Figure 1-3 As shown, the processing method of the full-color point-controlled video photoelectric glass described in the embodiment of the present invention mainly consists of the following steps:

[0035] (1) First, clean the conductive glass 2,

[0036] ⑵Introduce the compiled circuit etching program into the laser equipment;

[0037] (3) Send the cleaned conductive glass into the laser equipment, and etch the transparent wire 10 on the conductive layer 3;

[0038] (4) Attach the RGB three-in-one LED light source 4 to the corresponding transparent wire 10;

[0039] (5) Connect the electrodes of the RGB three-in-one LED light source 4 to the transparent wire 10 with conductive glue;

[0040] (6) Attach the circuit control board 5 to both sides of the glass, and connect all the tri-color RGB transparent wires 10 of the LED light sources 4 to the circuit control board 5 through conductive glue;

[0041] ⑺ Send the attached conductive glass 2 into the oven to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com