Metal film forming method of power MOS device

A MOS device and metal film forming technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as weak bonding degree, improve electrical performance and service life, and improve bonding performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

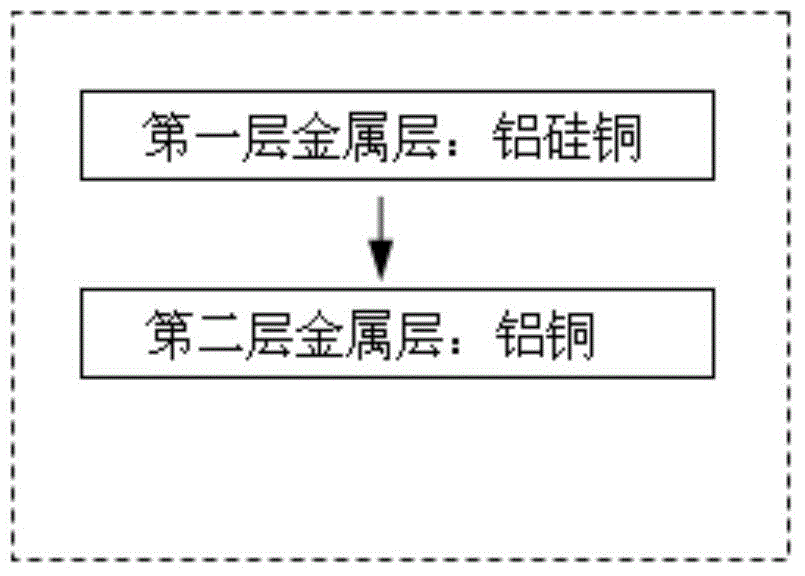

[0016] Such as image 3 Shown, a kind of metal film forming method of the present invention improves power MOS (power MOS) bonding performance, mainly comprises the following steps:

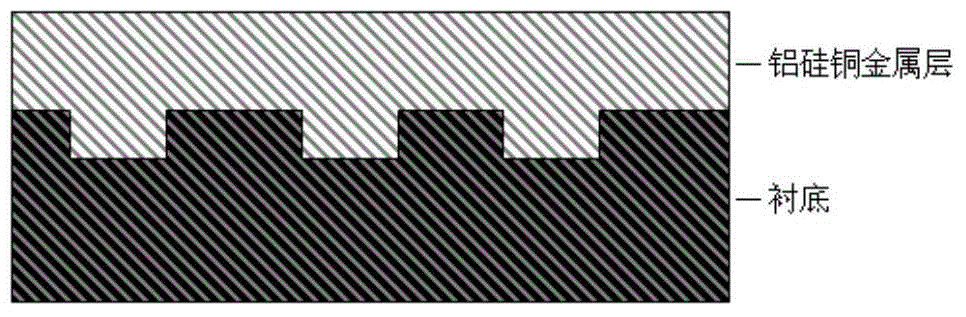

[0017] (1) The formation of the first metal layer, aluminum-silicon-copper; the film-forming substrate is a silicon substrate, and the film-forming substances on the surface include but are not limited to oxide film, polysilicon, metal titanium, titanium nitride and other substances; this step mainly adopts physical Sputtering film forming process, the film forming thickness is 10-40000 Angstroms, the sputtering temperature is 10-500°C, and the pressure is 1-100mtorr.

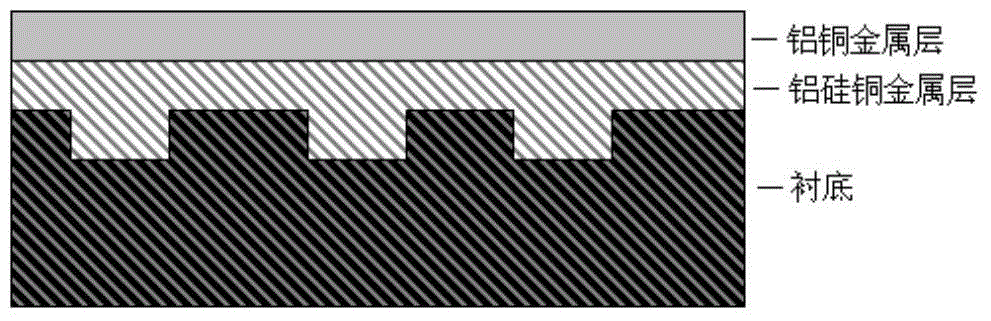

[0018] (2) The formation of the second metal layer of aluminum copper; this step mainly adopts the physical sputtering film forming process, the film thickness is 10-40000 angstroms, the sputteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap