Plastic-encapsulated type intelligent power module conveying system

A technology of intelligent power modules and transmission systems, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve problems such as time-consuming, pin bending, and large amount of material boxes, so as to avoid product quality. Problems, the effect of increasing the degree of automation and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

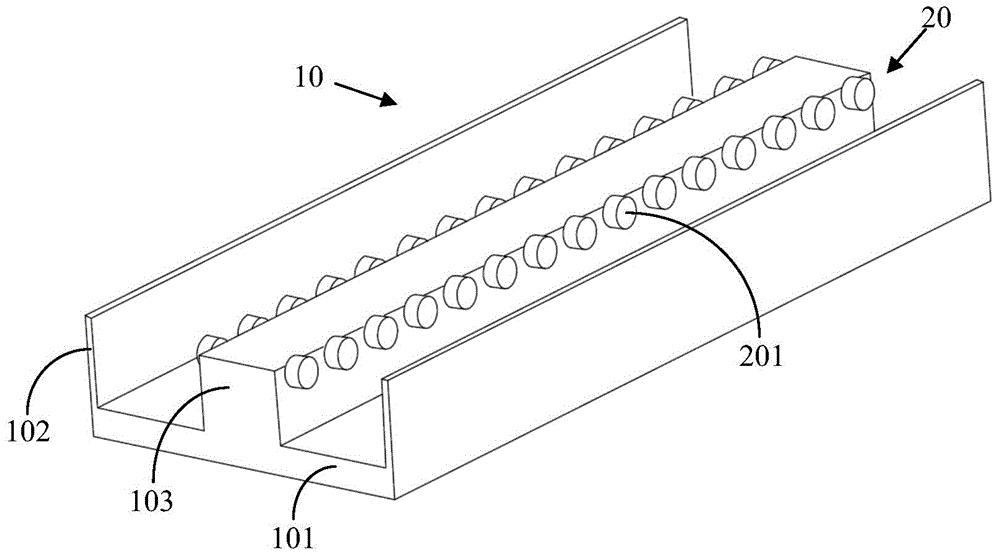

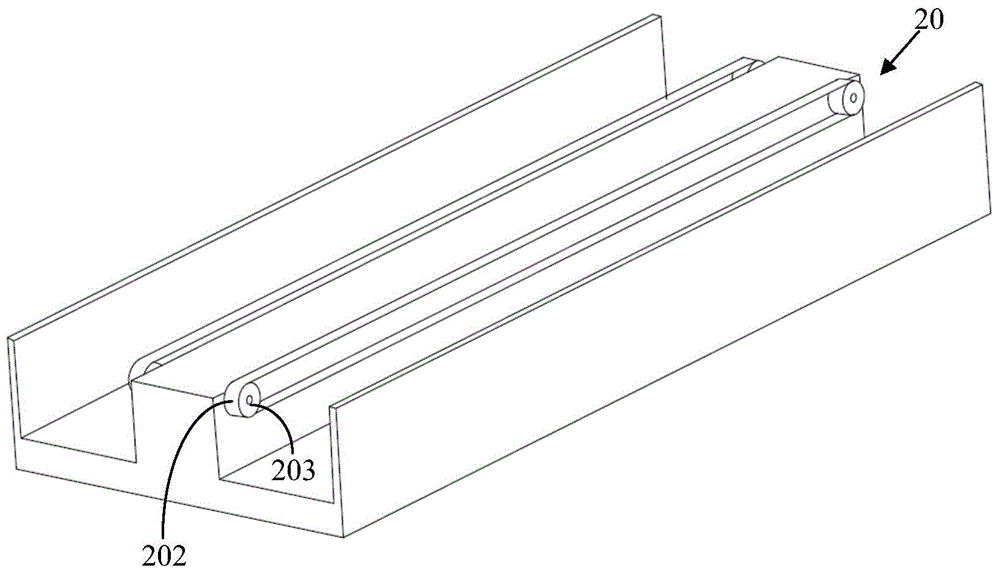

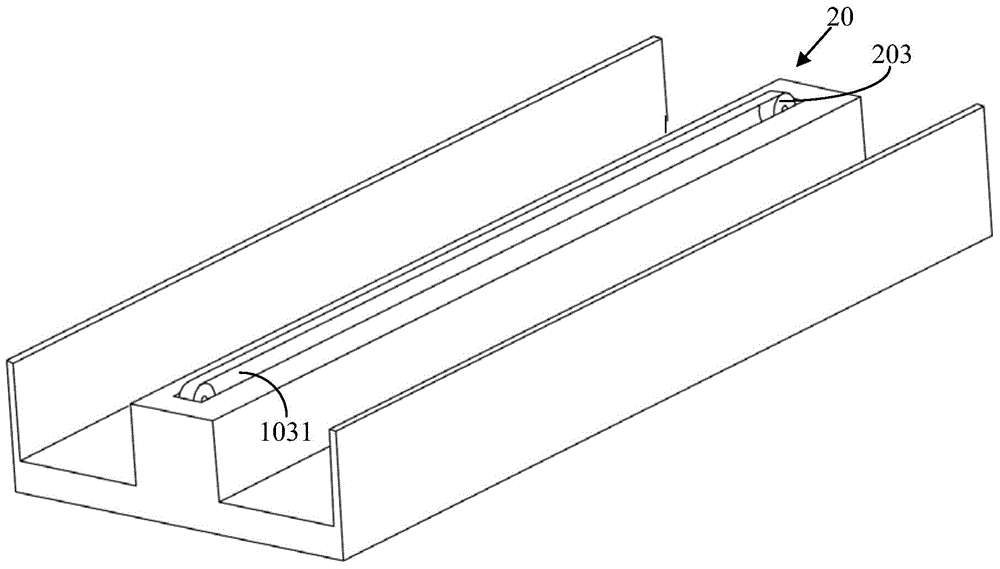

[0023] The invention discloses a plastic-encapsulated intelligent power module transmission system, which includes:

[0024] The rail device comprises a bottom plate, baffles arranged on both sides of the bottom plate and extending along the longitudinal direction, the bottom plate is provided with a raised portion between the baffles, the bottom plate, the two side baffles, the raised The starting part forms the transmission space of the plastic-encapsulated intelligent power module;

[0025] a conveying device, which is arranged on the guide rail device;

[0026] A driving device, which drives the conveying device to run.

[0027] Preferably, the number of the guide rail devices is two or more, and the plurality of guide rail devices form a transmission path of the plastic-encapsulated intelligent power module.

[0028] Preferably, the guide rail device has ports, and the positions of the ports of the two adjacent guide rail devices are corresponding.

[0029] Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com