Cord cutting terminal connection structure of stator, motor stator with cord cutting terminal connection structure, and connection method

A technology of terminal connection and stator, which is applied in the field of electric motor stator and connection, and the connection structure of wire-cutting terminals of the stator, which can solve the problems of affecting product production efficiency, affecting service life, cumbersome operation, etc. The effect of avoiding cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

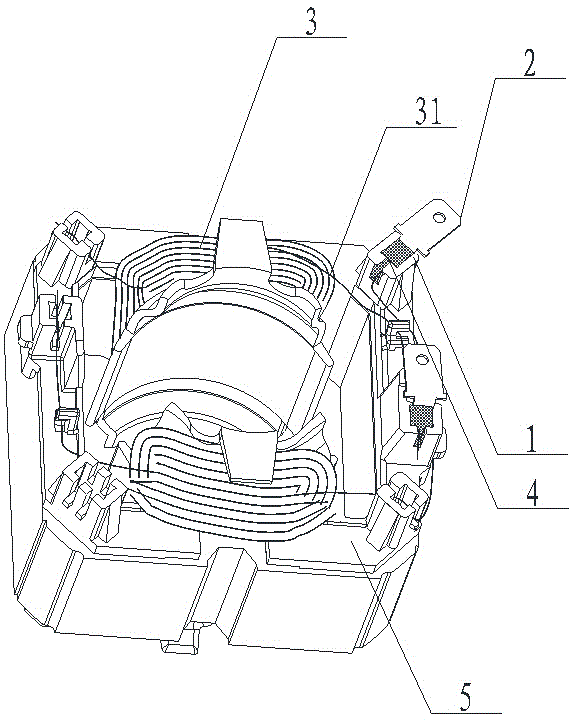

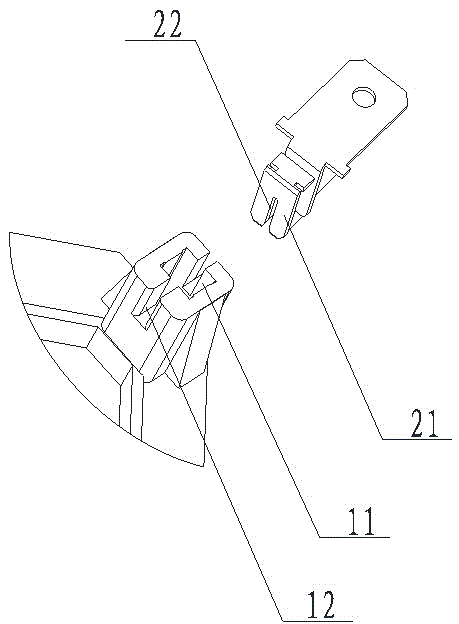

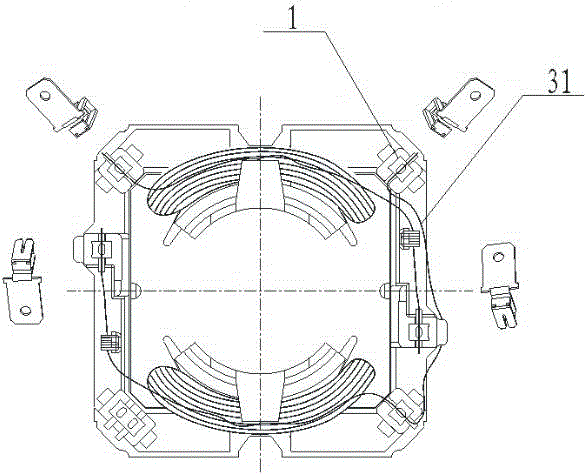

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1-3 As shown, in the first embodiment of the connection structure of the wire-cutting terminal of the stator of the present invention, it includes: a terminal chamber 1, which has a terminal groove 11 and a wire groove 12 communicating with each other; a terminal 2, which has a connecting part 21 , the connecting part 21 is provided with a second wire groove 22, the connecting part 21 is inserted into the terminal groove 11, and is fixedly connected with the terminal chamber 1, and the second wire groove 22 is set facing the wire groove 12; the joint part 31 of the aluminum wire 3 is arranged in the wire groove 12 and the second wire groove 22; the fixing layer 4 is arranged between the terminal cavity 1, the terminal 2 and the joint part 31. This wire-cutter terminal connection structure fixes the joint part 31 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com