Magnetic suspension type stirring method and device

A stirring method and magnetic levitation technology, which is applied to chemical instruments and methods, dissolution, mixers, etc., can solve problems such as inconvenient use, poor safety, and high energy consumption, and achieve the effects of ensuring safety and sanitation, improving service life, and solving mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In conjunction with the accompanying drawings, the present invention is further described in detail through embodiments. However, the present invention is not limited to the following examples.

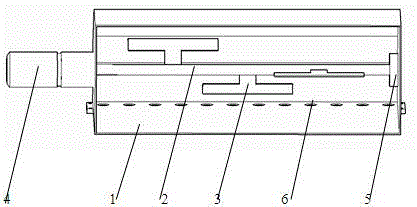

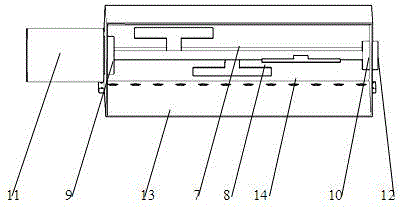

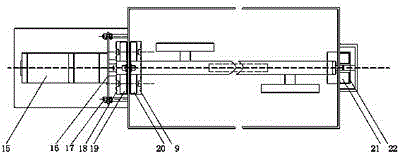

[0031] The magnetic levitation stirring method described in this embodiment is to set magnetic materials on both sides of the material box 13 and on the output shaft of the motor, and utilize the characteristics of magnets that "same sex repels each other and opposite sexes attract each other" to make the stirring shaft 7 horizontally suspend on the material. In the box 13, the transmission mode without mechanical connection between the motor and the stirring shaft 7 is realized. The output power of the motor drives the stirring shaft 7 to rotate through the magnetic material, and at the same time drives the stirring blade 8 connected to the stirring shaft 7 to rotate, thereby continuously stirring the mixed slurry in the material box 13 .

[0032] The specific measures taken ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com