Clamping mechanism

A clamping mechanism and frame technology, applied in the direction of clamps, collets, manipulators, etc., can solve the problems of high manufacturing cost, large labor force, poor precision, etc., and achieve the effect of automatic production, labor saving, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

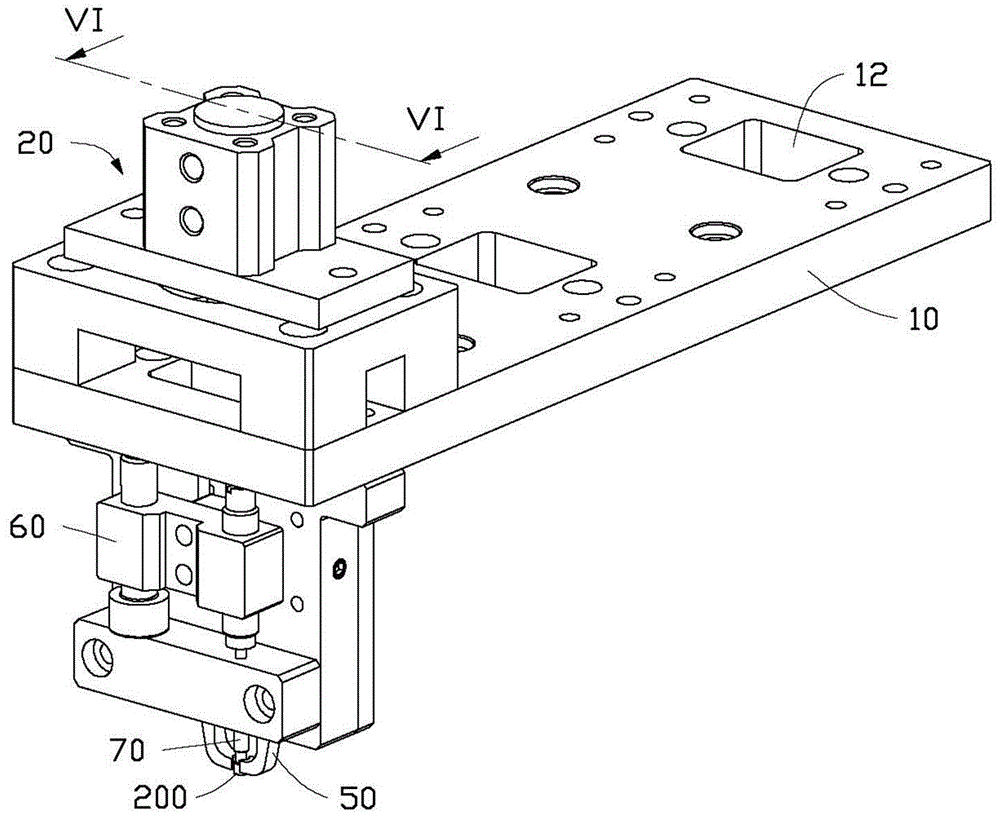

[0016] see figure 1 with image 3 , the present invention provides a clamping mechanism 100 for clamping a workpiece, such as a nut 200 . The clamping mechanism 100 includes a connecting plate 10 , a cylinder assembly 20 , a frame 30 , a returning assembly 40 , a clamping assembly 50 , a limiting assembly 60 and a positioning assembly 70 . The connecting plate 10 is used for installing the cylinder assembly 20 , and the frame 30 is used for installing the returning assembly 40 and the clamping assembly 50 .

[0017] At least one installation hole 12 is opened on the connection board 10 . At least one set of cylinder assembly 20 and frame 30 are mounted on the connecting plate 10 corresponding to the mounting holes 12 . The cylinder assembly 20 is fixed on one side of the connecting plate 10 for providing power in the vertical direction for the clamping mechanism 100 . The cylinder assembly 20 includes a connecting rod 21 passing through the mounting hole 12 to connect to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com