Composite material door panel for bottom side door of open top wagon and preparation method thereof

A composite material and side door technology, applied in chemical instruments and methods, synthetic resin layered products, glass/slag layered products, etc., can solve the problem of mechanical properties that are difficult to withstand train transportation conditions, outdoor exposure and rain erosion, Unable to recycle and use, etc., to achieve good resilience, easy installation, and no permanent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Preparation:

[0033] Lay the prepreg tape neatly according to the angle to a predetermined thickness; add a layer of non-woven fabric on the upper and lower surfaces of the prepreg tape layer; prepare the laid prepreg tape layer and non-woven fabric by molding method to obtain the lower side door of the gondola Composite door panels.

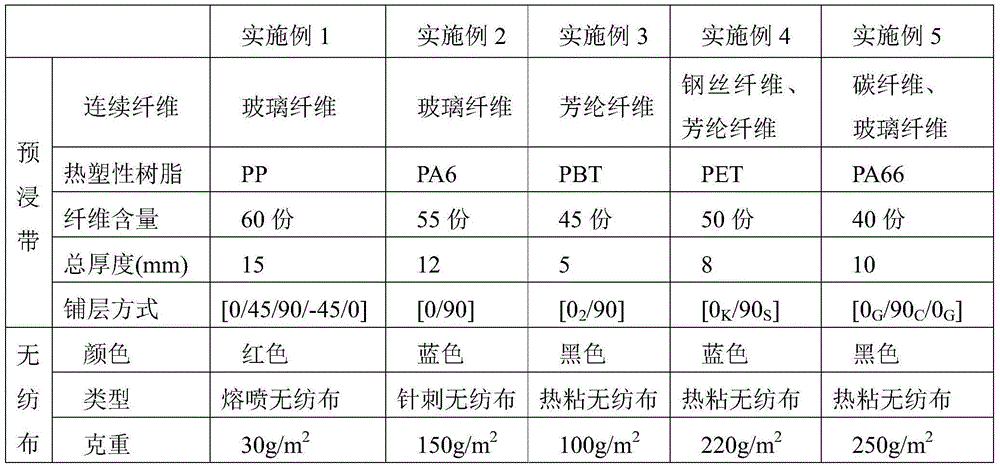

[0034] Prepare materials according to the prepreg tape and non-woven fabric in Table 1, cut them neatly according to the size, and lay them up to a predetermined thickness according to the layering method; after the prepreg tape layer and non-woven fabric are molded by compression molding, Test its performance as shown in Table 2.

[0035] Table 1 Example prepreg tape and non-woven fabric proportioning

[0036]

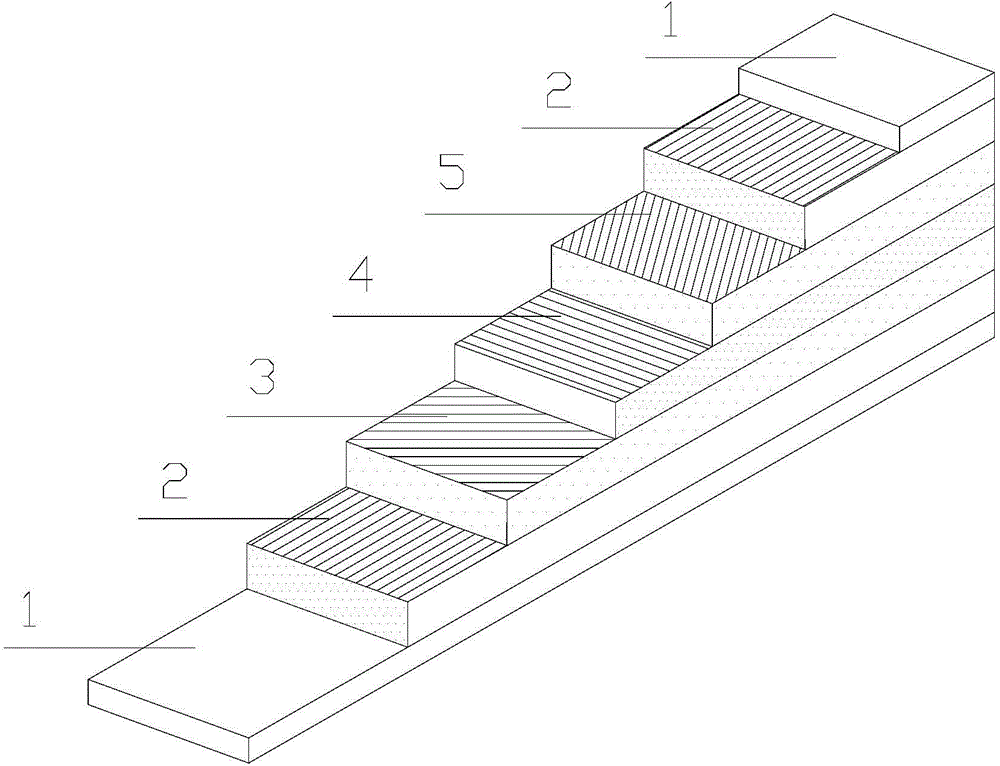

[0037] The layering method is as figure 1 As shown, 1 is a non-woven fabric layer, 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com