Modified calcium oxide expansive agent used for cement concrete and preparation method thereof

A technology of cement concrete and calcium oxide, applied in the field of building materials, can solve the problems of easy moisture absorption failure, hydration waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

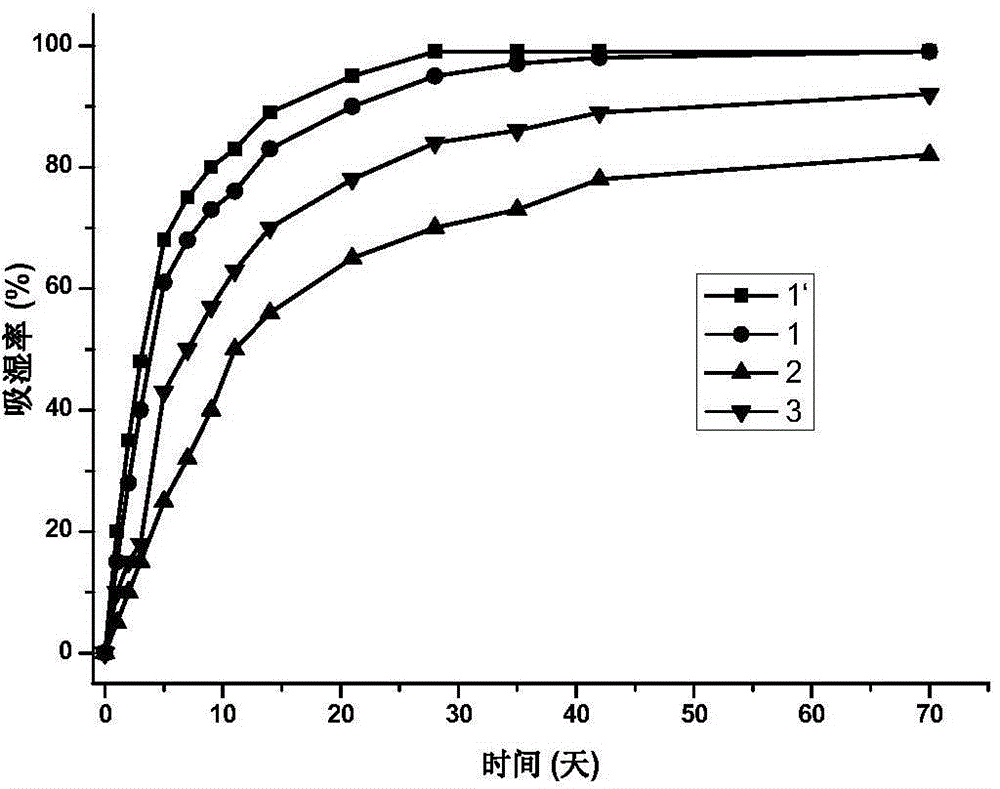

Embodiment 1

[0042] Weigh calcium oxide-based expansion clinker and redispersible latex powder with a mass ratio of 999:1, mix them and place them in an electromagnetic vibrating mill for grinding for 0.1 min to obtain the modified calcium oxide-based cement concrete expansion agent 1 .

Embodiment 2

[0044] The calcium oxide-based expansive clinker and redispersible latex powder with a mass ratio of 99:1 were weighed, mixed evenly and placed in an electromagnetic vibrating mill for grinding for 2 minutes to obtain the modified calcium oxide-based cement concrete expansion agent 2.

Embodiment 3

[0046] Weigh calcium oxide-based expansive clinker and redispersible latex powder with a mass ratio of 995:5, mix them and place them in a continuous powder surface modification machine for grinding for 3 minutes to obtain the modified calcium oxide-based cement concrete expansion Agent 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com