Rock block gravity-type retaining wall and construction method thereof

A construction method and a gravity type technology, applied in the field of block stone gravity type retaining wall and its construction, can solve the problems of inability to meet the requirements of concrete construction progress, long age requirements of design strength, poor economy and safety, etc. The effect of short construction period, convenient material collection and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

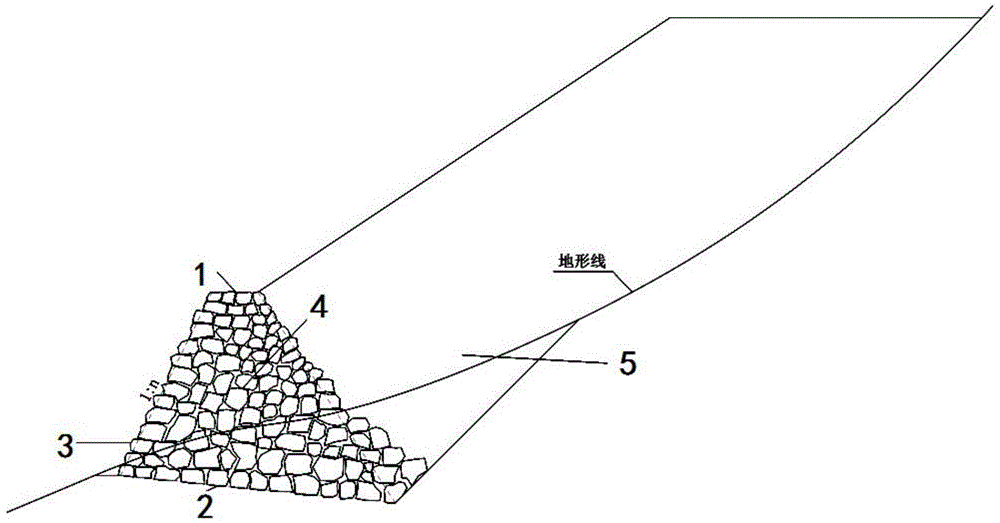

[0027] A construction method of block stone gravity retaining wall, the design points are as follows:

[0028] 1. Material selection:

[0029] The relevant physical properties of the block stone used for the retaining wall need to meet the mechanical construction requirements of the retaining wall, and the general requirement is fresh or weakly weathered rock. The side length of the mining block is required to be 0.5m<a<1.5m.

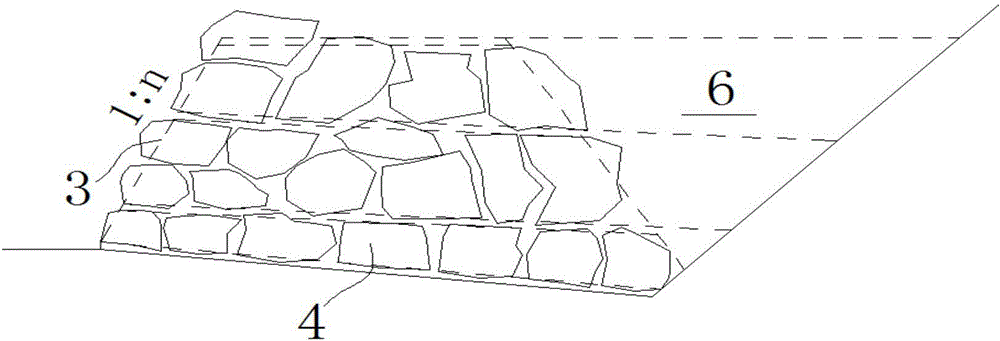

[0030] 2. Structural design:

[0031] 1. The base of the retaining wall should be horizontal or inclined inward; when it is inclined outward, the base should be designed in a stepped shape.

[0032] 2. The slope ratio of the retaining wall is 1:n=1:(0.3~1.0), the width of the top of the wall is generally 1~2m, the width of the bottom of the wall is slightly larger than the height of the retaining wall, and the slope ratio of the non-air face Determined by stability analysis calculations.

[0033] 3. In addition to the overall anti-sliding and overtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com