Construction method for evacuating subway station by prefabricated structure cover

A technology for subway stations and construction methods, applied in infrastructure engineering, water conservancy projects, underwater structures, etc., can solve problems affecting backfilling time, many roads, aggravating traffic congestion, etc., increase anti-floating ability, and have obvious social benefits , The effect of saving building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

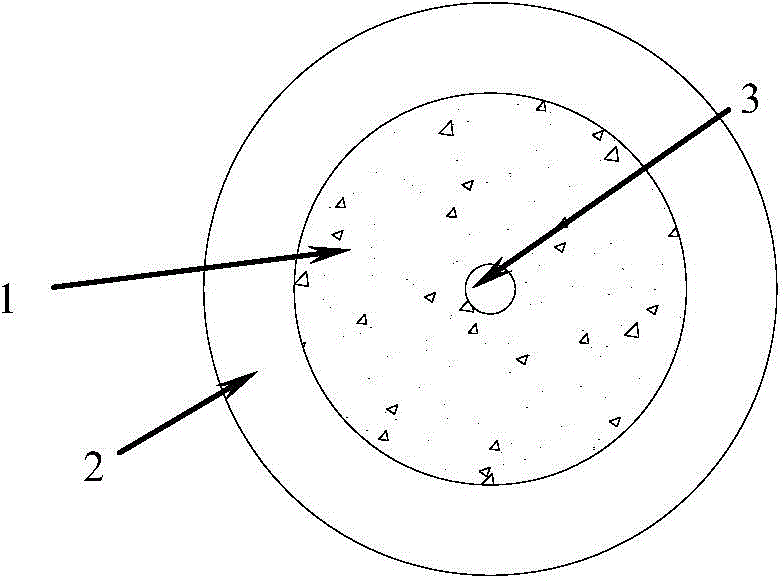

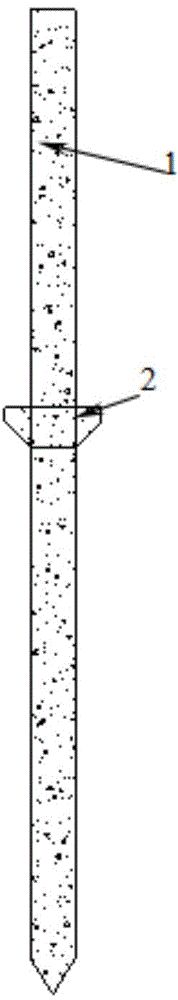

[0067] Such as figure 1 , image 3 As shown, the prefabricated enclosure pile 1 is a reinforced concrete structure, the enclosure pile 1 is provided with an enclosure pile corbel 2, and the center of the enclosure pile 1 is provided with an enclosure pile grouting hole 3 along the axial direction.

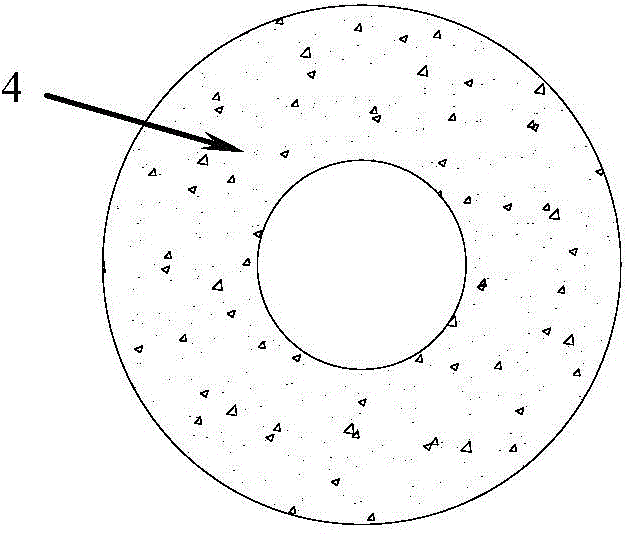

[0068] Such as figure 2 , Figure 4 As shown, the prefabricated column pile 4 is a hollow reinforced concrete structure to reduce dead weight and save materials.

[0069] Such as Figure 5 , Image 6 As shown, there is a rib in the middle of the top of the prefabricated laminated slab 5, which is the same as the length of the prefabricated laminated slab 5 in the extending direction of the rib, and the rib 6 is reserved on the rib, which can be connected with the reinforcement in the upper cast-in-place structure. together to increase stability.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com