A prefabricated alcove-type construction technology with reserved holes for household electric boxes

A construction technology and a technology for housing division, applied in the direction of electrical components, etc., can solve the problems that the walls cannot be preserved, affect the owner's use function, and cannot meet the needs of on-site production, so as to improve the rate of excellence and customer satisfaction, and facilitate large-scale production The effect of popularizing applications and reducing late-stage cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

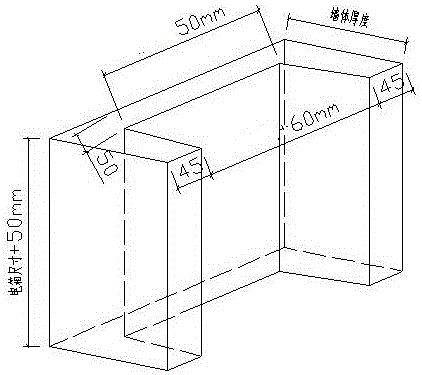

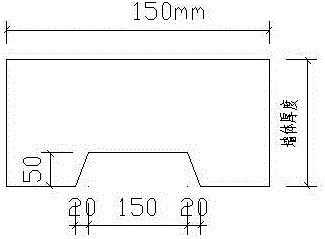

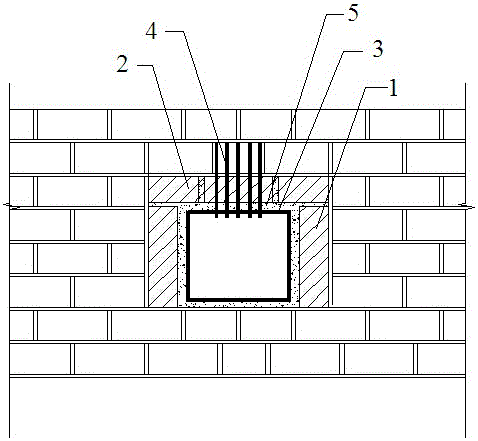

[0024] A prefabricated alcove-type construction process for the reserved hole of the residential household electric box, the construction process includes the following steps: 1) The reserved hole of the residential household electric box adopts a prefabricated alcove-shaped component, and the alcove-shaped component is surrounded by a U-shape The guard plate 1 and the cover plate 2 with trapezoidal grooves are reserved. Firstly, the alcove-type frame member is made. The specific manufacturing process of the alcove-type frame member is as follows, 11), see figure 1 , U-shaped enclosure frame 1 cavity is a trapezoidal opening, the inner width is 10mm smaller than the outer width, the inner width is 50mm for the electrical box size, and the outer width is 60mm for the electrical box size; 12), the outer sides of the U-shaped enclosure frame The thickness is 45 mm, the inner side is 50 mm thick, the back panel is 50 mm thick, and the cover plate is 50 mm thick. For details, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com