T-shaped range hood with multiple layers of oil fume separation meshes

A technology of oil fume separation net and oil fume machine, which is applied in the direction of removing oil fume, household heating, lighting and heating equipment, etc. Improve and improve the separation rate of oil fume and reduce the effect of oil fume escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

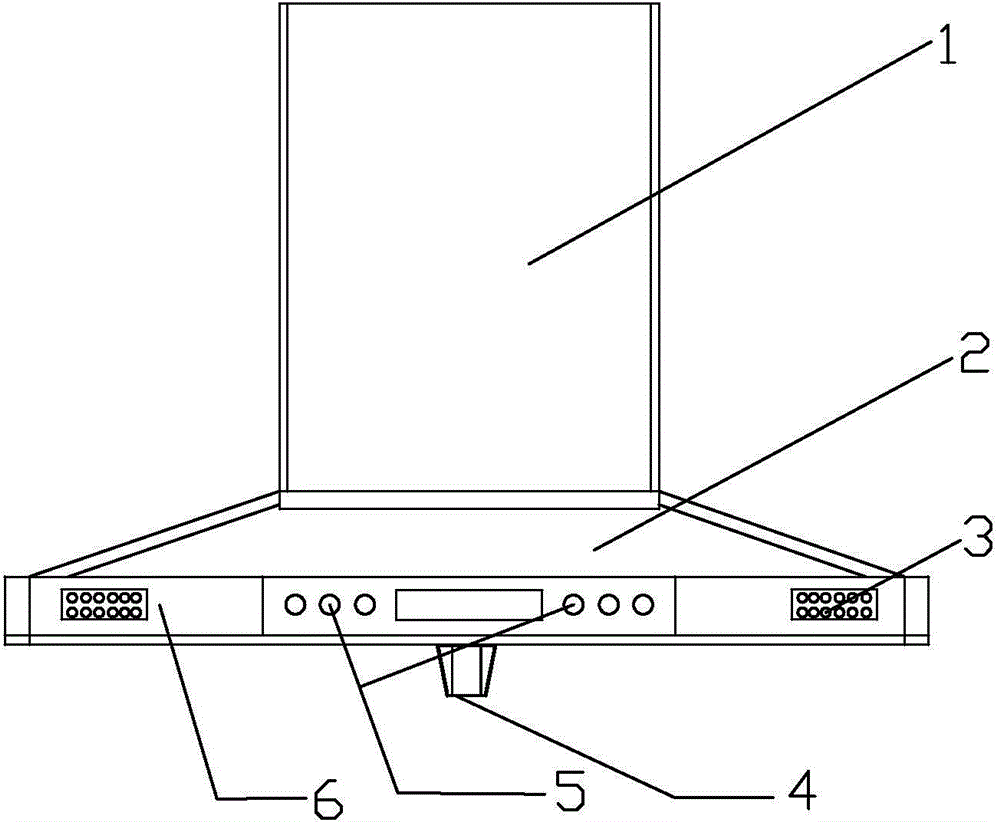

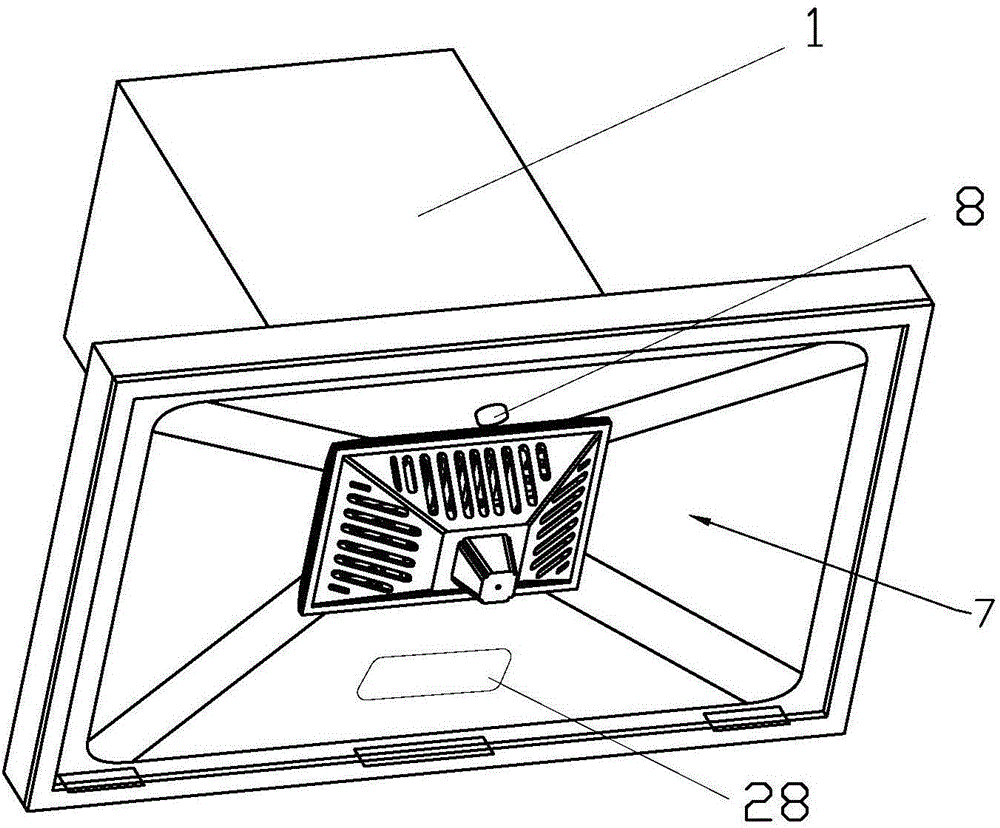

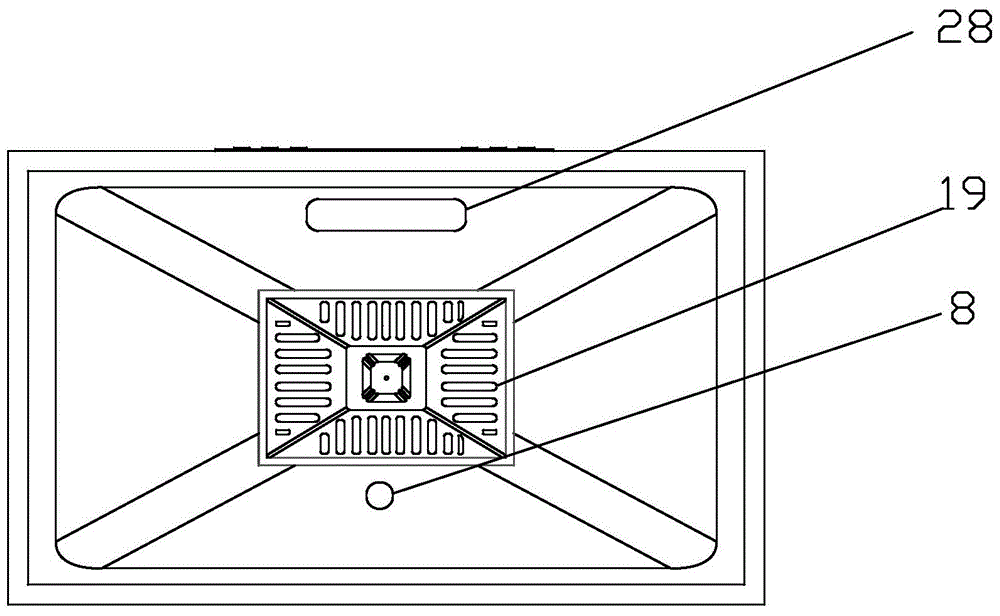

[0029] Embodiment 1: In this embodiment, see Figure 1-Figure 10 , a T-shaped range hood with a multi-layer oil fume separation net, comprising a casing 2, an external oil fume separation net 19, a middle layer oil fume separation net 13, a built-in oil fume separation net 9, an oil cup 4, a motor 27, and a motor bracket 18 The volute 15, twin turbines 16, smoke sensor 8 and other hood components, the smoke cavity 7 in the casing is a pyramid cavity with a certain inclination angle, the bottom of the cavity is installed with an external oil fume net 19, and the upper part is equipped with a middle layer oil fume net 13, The built-in oil fume net 9 and the external oil fume net 19 are provided with hooks, and the oil cup 4 is provided with a matching hanging sticker 22, which is used to realize the installation and disassembly of the oil cup through the cooperation of the hook and the hanging sticker.

[0030] In this example, see Figure 1-Figure 10 , the external oil fume se...

Embodiment 2

[0041]This embodiment is basically the same as Embodiment 1, especially in that:

[0042] In this embodiment, the operation panel 6 is controlled by a touch screen and remotely controlled by wireless bluetooth communication technology. The range hood can be operated in the bedroom and living room outside the kitchen. , The range hood is automatically turned off, realizing automation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com