Device and method for adjusting zero sensor

A technology of zero position sensor and adjustment device, which is applied in the direction of measuring device, optical device, photo-plate making process exposure device, etc., and can solve the problems of affecting accuracy and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

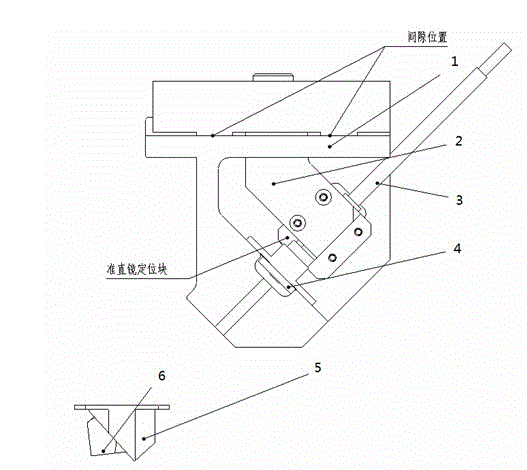

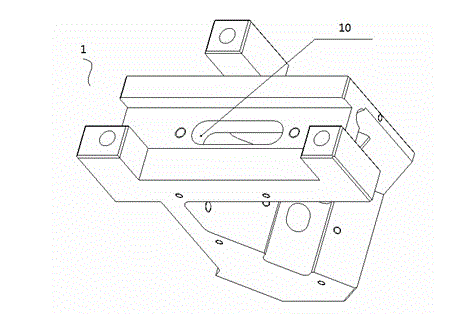

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

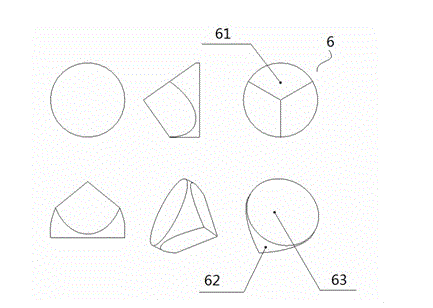

[0036] The shape of the corner mirror 6 is as follows image 3 As shown, it has three light reflecting surfaces with excellent perpendicularity. image 3 Among them, 61 is a light reflecting surface, 62 is a cylindrical surface, and 63 is a large circular end surface. According to this characteristic, the incident light from any direction within the cone angle within an angular range deviated from the cylindrical axis (optical axis) of the retroreflector will be reflected back in parallel.

[0037] like Figure 4 As shown, on the large circular end face 63 of the corner cone reflector 6, when the incident light moves away from the central optical axis of the corner cone reflector, according to the characteristics of the corner cone reflector, the reflected light will also move away from the center optical axis of the corner cone reflector T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com